CNC Cutting Technology – The Modern Trend In Metal Fabrication

In today’s industrial era, CNC (Computer Numerical Control) cutting has become an inevitable trend in metal fabrication thanks to its high precision, superior efficiency, and flexible customization. With the advancement of modern machinery, CNC cutting has gradually replaced many traditional methods, bringing significant benefits to the mechanical and construction industries.

1. What is CNC cutting?

CNC cutting is a metal fabrication method that uses computer-controlled cutting machines to execute complex cuts with high accuracy. It can be applied to a wide range of materials including steel, aluminum, copper, stainless steel, and even non-metallic materials.

2. Popular CNC cutting methods

There are several CNC cutting methods, each suitable for specific materials and technical requirements:

- CNC laser cutting: Uses laser beams to create sharp, precise, and high-speed cuts, ideal for components requiring fine details.

- CNC plasma cutting: Applies plasma arcs for fast cutting, effective for medium to thick steel plates.

- CNC oxy-gas cutting: Utilizes oxygen and fuel gases to cut thick metals, suitable for heavy industries.

- CNC waterjet cutting: Employs high-pressure water mixed with abrasives to cut heat-sensitive materials.

3. Key advantages of CNC cutting

- High precision: Computer control minimizes errors and meets strict production requirements.

- Increased productivity and lower costs: Automation saves time and labor, improving efficiency.

- Material versatility and design flexibility: Suitable for a wide range of materials and complex designs that traditional methods struggle to achieve.

- Consistent product quality: Reduces human errors and ensures uniformity across products.

4. Applications of CNC cutting

CNC cutting is widely applied across various industries:

- Mechanical engineering: Machining machine parts, mold making, and steel plate cutting.

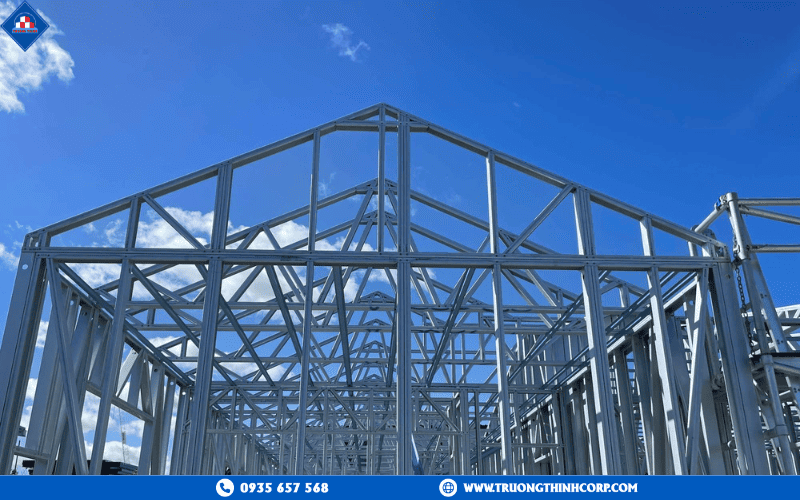

- Construction: Fabrication of steel structures for buildings and pre-engineered projects.

- Automotive, shipbuilding, aerospace: Producing high-precision metal components with stringent technical requirements.

- Interior design: Creating decorative metal patterns and customized designs.

5. Future trends in CNC cutting

CNC cutting technology will continue evolving with trends such as:

- Automation and AI integration: Enhancing process optimization and minimizing errors.

- IoT connectivity: Enabling remote monitoring and machine control for higher operational efficiency.

- Non-contact cutting technologies: Such as laser and waterjet, minimizing thermal impacts on materials.

CNC cutting not only improves product quality but also drives the growth of the metal fabrication industry. Investing in this technology is a strategic step for businesses to enhance competitiveness and meet increasing market demands.

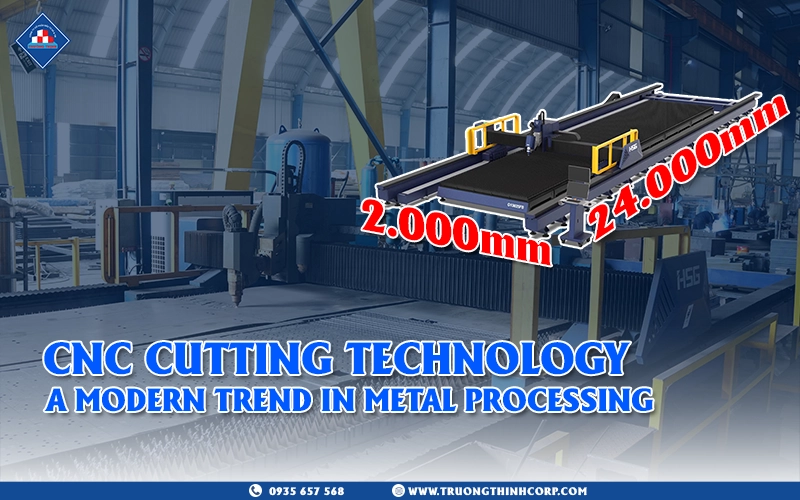

6. Truong Thinh Factory – A pioneer in CNC cutting technology

Truong Thinh Steel Structure Factory is equipped with modern machinery, especially high-power CNC Laser cutting machines ranging from 15 to 20 HP. These machines are capable of cutting steel plates up to 60mm in thickness vertically and 35mm at beveled angles, meeting the most demanding requirements from small components to large-scale complex projects.

With outstanding advantages in precision, speed, and cutting aesthetics, CNC Laser technology at Truong Thinh not only enhances product quality but also optimizes production time, effectively catering to diverse customer needs.