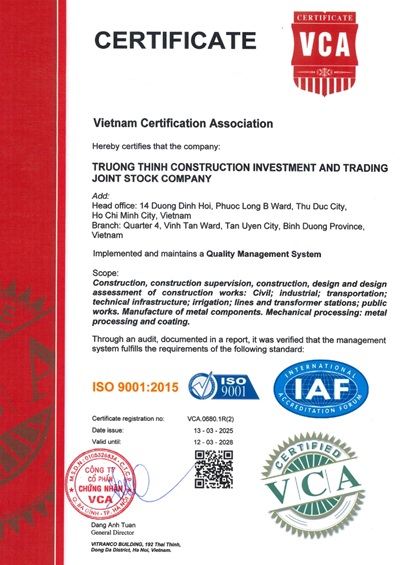

ISO 9001 is an international quality certification, ensuring all production processes meet high standards, bringing reliability.

Production Capacity

Streamlined

Production Process

An end-to-end production workflow integrates design, fabrication, surface treatment, and on-site installation. Backed by ISO 9001:2015 standards, advanced CNC technology, and expert engineering teams, every stage is optimized to ensure precision, speed, and global export quality.

01.

Structural Design & Simulation

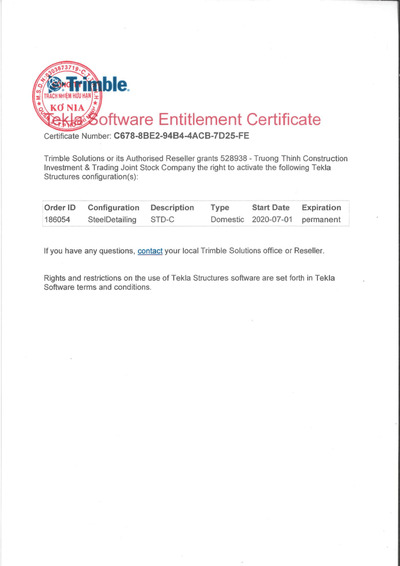

BIM and Tekla technologies are used to ensure complete accuracy during fabrication.

02.

Consultation & Cost Optimization

Senior engineers provide load analysis and design optimization, achieving up to 12% savings on material costs.

03.

Fabrication, Coating and Quality Control

A closed-loop process with ultrasonic testing ensures surfaces meet the Sa… standard.

04.

Transportation, Assembly & After-Sales

An in-house team ensures delivery within 6 months for capacities up to 10,000 tons. Every project is supported by warranty, regular maintenance checks, and dedicated after-sales service to guarantee long-term quality and reliability.

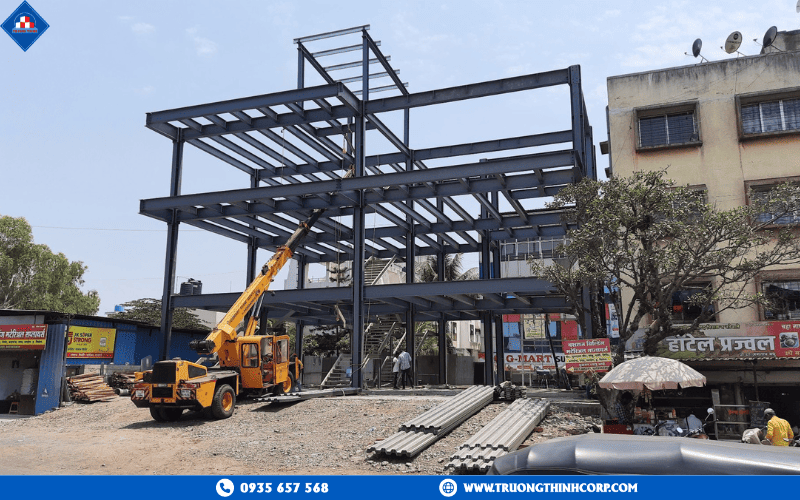

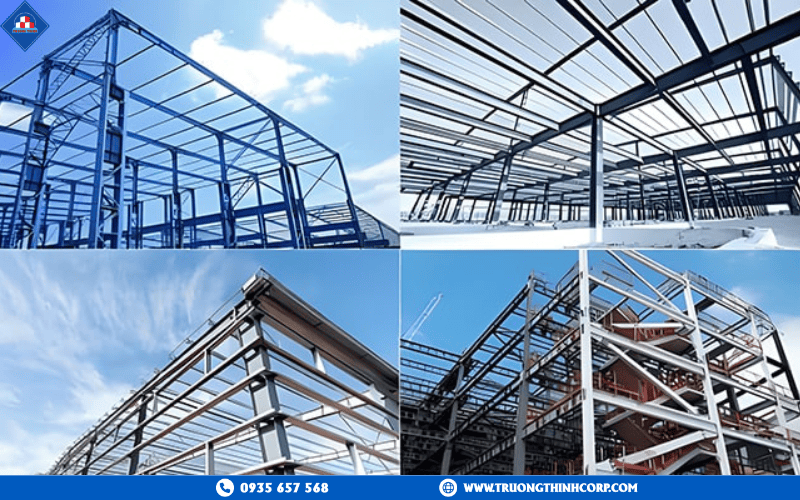

Showcase Project

Truong Thinh is executing several flagship projects in the construction and steel fabrication sectors, making significant contributions to infrastructure development.

Dabaco Production Plant

- Completion Time 2018

- Scale 10000 m2

Dabaco

NPK Fertilizer Plant

- Completion Time 2017

- Scale 5000 m2

NPK

Khang Dien Residential Area

- Completion Time 2017

- Scale 350 m2

Khang Dien

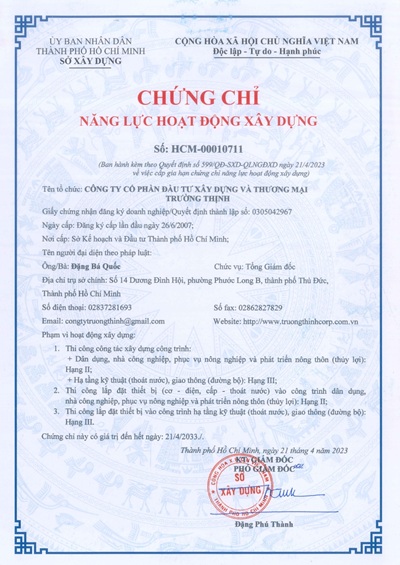

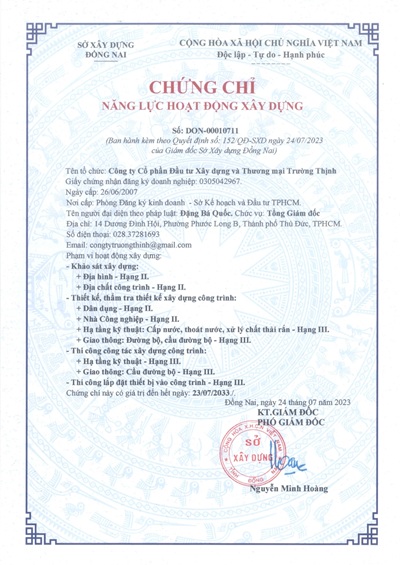

Certificate of Manufacturing and Construction Capacity

Our

Partners

We are proud to be a leading company in the industry.

As a trusted leader in steel structure and construction, we are committed to delivering quality and reliability in every project. Connect with us today to discuss your needs and explore how we can build success together.

News

Explore industry news, global market trends and company updates in steel structures and beyond.

Steel Structures in Hotels Construction: Applications, Benefits and Investment Value

Steel Structures in Convention Halls Construction

Steel Structures in Exhibition Centers Construction for Large Span Buildings

Which Is Better: RCC or Steel Structure?

Which Steel Is Best for a Residential Building?

Components of a Steel Structure: A Complete Technical Overview

Frequently Asked Questions

Placeholder text for content. This is a sample sentence.

Clients collaborate with Truong Thinh through a transparent, step-by-step process:

1. Requirement analysis & consultation: Defining project scope, budget, and schedule.

2. Design & engineering: Delivering technical drawings and structural optimization.

3. Manufacturing: High-precision fabrication at our 25,000 m² facility.

4. Logistics & delivery: Efficient shipping and handling for both domestic & overseas projects.

5. Construction & erection: On-site assembly, testing, and quality checks.

6. Handover & after-sales service: Long-term maintenance and technical support.

This streamlined approach ensures clients receive a cost-effective, high-quality solution delivered on time and tailored to international requirements.

The process begins with conceptual design and technical consultation, where client requirements are translated into optimized structural solutions:

Our engineers then use internationally recognized software (AutoCAD, Revit, SAP2000, Tekla Structures) to create detailed drawings.

After approval, materials are fabricated in our ISO 9001:2015-certified steel plant using CNC technologies to ensure precision.

Finally, components are shipped and assembled on-site by our experienced erection teams, guaranteeing efficiency, safety, and compliance with global standards.

Timeframes vary depending on scale, complexity, and location of the project:

Design & engineering: 2–4 weeks for standard factory/PEB projects.

Fabrication & manufacturing: 4–8 weeks depending on volume (average 1,200–1,500 tons/month capacity).

Erection & completion: 6–12 weeks for medium-scale projects, adjusted to project size.

In total, most factories or pre-engineered steel buildings are completed within 3–6 months from design approval to handover—offering international clients both speed and assurance of quality.