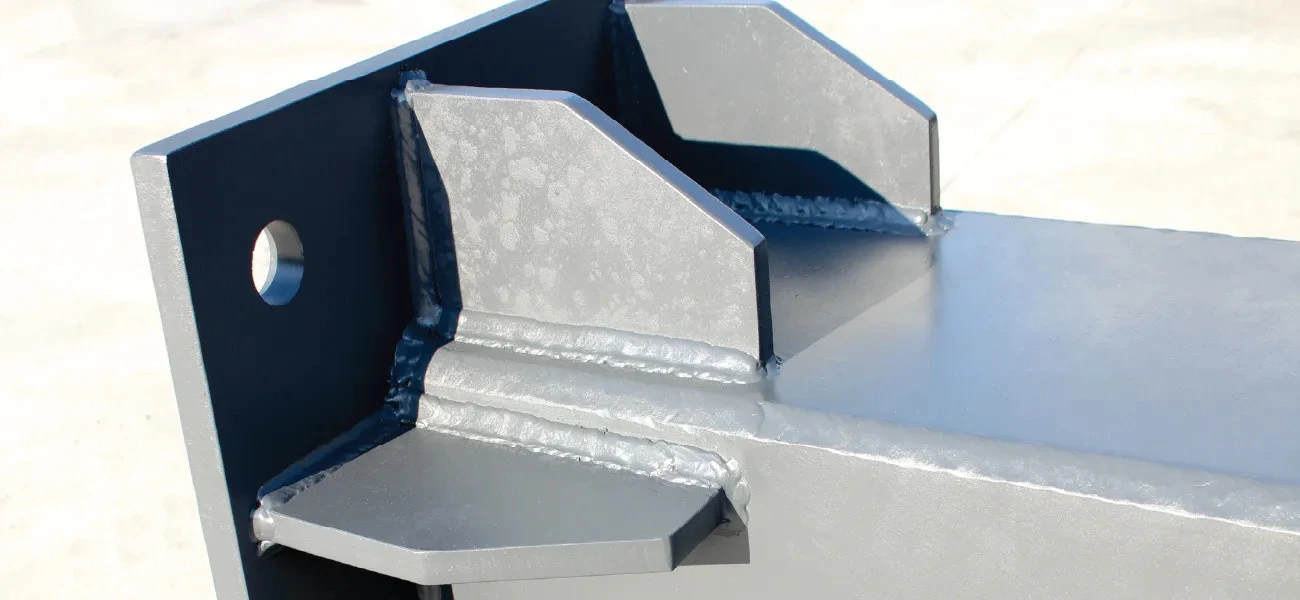

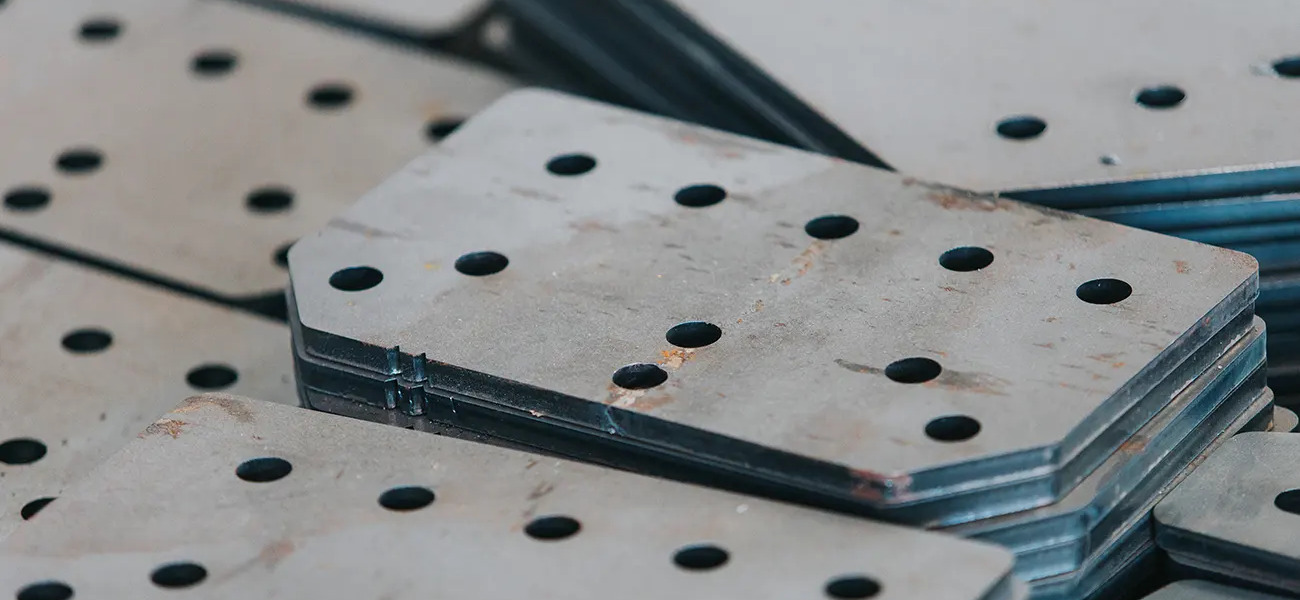

CNC Laser Cutting Technology

CNC Laser Cutting Machine provides exceptional precision and efficiency in steel processing. With a working size of 2m × 26m and a maximum cutting thickness of 60mm, it delivers clean, accurate cuts for large-scale steel plates. Powered by a 30HP system and capable of beveled edge cutting angles from 0° to 60°, this technology guarantees top-quality results for even the most complex designs.