Company Specializing in Manufacturing and Supplying C and Z Steel Purlins

Steel purlins are a common structural element used for roofing and flooring systems in factories, warehouses, and modern industrial facilities due to their durability, load-bearing capacity, and fast installation. Compared to traditional timber purlins, steel purlins offer significant long-term cost savings, reduced structural weight, shorter construction timelines, and minimal deformation over time. Truong Thinh Corp takes pride in being a trusted manufacturer and supplier of high-quality steel purlins for both domestic and international markets. Our modern steel structure factory spans 25,000 m², equipped with advanced forming and fabrication lines, and operates under the ISO 9001:2015 quality management system to ensure consistent excellence across all products.

1. Steel purlins in industrial construction

In modern industrial buildings, steel purlins play a vital role in supporting the roof system, transferring loads to the frame of steel truss and ensuring overall stability. Thanks to their high strength, lightweight design, fast installation, and long service life, steel purlins have increasingly replaced traditional materials such as wood.

1.1 What is a purlin?

A purlin is a horizontal structural member designed to support the roof or lightweight floor of a building, transmitting loads from the roof cladding down to the rafters or columns. In pre-engineered steel buildings (PEBs), purlins are one of the most critical components that help the roof withstand loads from wind, snow, roofing sheets, and other ancillary elements.

Depending on design requirements, purlins can be made from wood, steel, or composite materials. However, in modern industrial applications, steel purlins—typically in C or Z profiles—are the preferred choice for their superior mechanical strength, high load-bearing capacity, and flexible installation.

1.2 Steel purlins vs. timber purlins

- Superior strength and load capacity

Steel offers tensile and compressive strengths many times greater than wood. According to ASTM A36, the tensile strength of steel is approximately 400–550 MPa, while that of wood averages only 40–80 MPa. This means steel purlins can carry heavier loads and ensure safety in wide-span roofing structures. Additionally, steel is resistant to termites, decay, shrinkage, and warping—common issues that severely affect the long-term performance of timber components.

- High consistency and dimensional accuracy

Steel purlins are mass-produced using automated roll-forming lines or CNC fabrication systems, ensuring uniform thickness, section size, and length. The dimensional tolerance is typically within ±1 mm, allowing for precise assembly and reducing adjustment time during installation. This precision is particularly crucial for large-scale projects, where even minor deviations can impact the entire roof structure.

- Lightweight and fast installation

Compared to traditional materials, steel purlins offer a high strength-to-weight ratio, making them lighter while maintaining excellent load-bearing capacity. This helps reduce foundation and frame loads and shorten construction timelines due to easier handling and assembly. For factories and warehouses with tight schedules, this is a major advantage.

- Long-term cost efficiency

Although the initial investment may be higher than wood, steel purlins deliver superior long-term economic efficiency. With galvanized or anti-corrosion coatings, they can maintain their structural integrity for decades with minimal maintenance. The average service life of steel purlins ranges from 30 to 50 years, compared to 10 to 15 years for timber purlins, depending on usage conditions. When evaluating the total life-cycle cost, steel purlins offer substantial savings for investors.

2. Types of steel purlins manufactured by Truong Thinh

Truong Thinh Corp is one of Vietnam’s leading manufacturers of C and Z steel purlins, trusted by both domestic and international clients. Our purlins are fabricated from high-quality galvanized or black steel coils with full CO/CQ certification, meeting all technical requirements for industrial structural applications. The two main product lines — C steel purlins and Z steel purlins — each offer distinct structural characteristics, load capacities, and design advantages suited to different types of buildings.

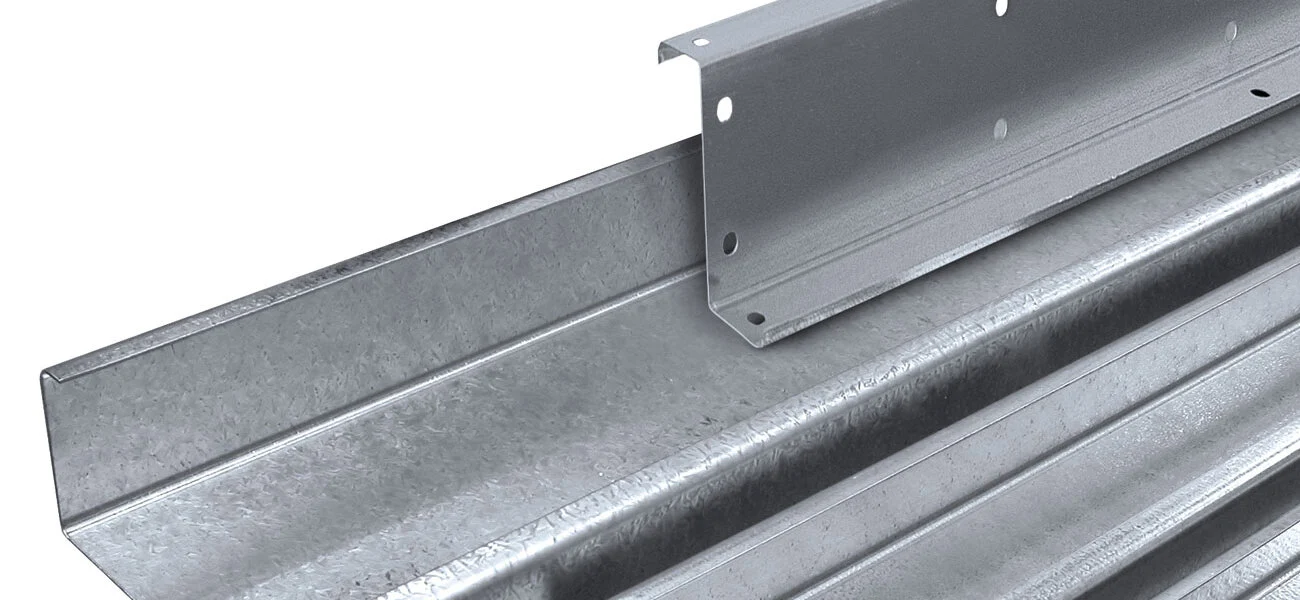

2.1 C Steel purlins

C-shaped steel purlins feature a C-section profile with two parallel flanges and a central web, roll-formed from galvanized or black steel sheets with thicknesses typically ranging from 1.5 mm to 3.0 mm, depending on design load requirements. At Truong Thinh, production is carried out on automated roll-forming lines, ensuring precise dimensions for:

- Web height: C80 – C250

- Flange width: 30 – 70 mm

- Folded edges: Reinforced for greater stiffness and stability

All punching and cutting operations are performed using CNC punching and cutting machines, guaranteeing dimensional accuracy, correct hole positioning, and precise fit-up according to shop drawings. This high precision significantly reduces assembly time on-site.

Thanks to their lightweight design and flexibility, C purlins are ideal for small- to medium-span structures. They can be easily connected using bolts or welding, making installation and dismantling convenient when needed. With consistent sizing and smooth edges, Truong Thinh’s C purlins ensure fast, error-free assembly and minimal adjustment during installation.

Economically, C purlins are a cost-effective choice due to their low material waste, ease of fabrication, and competitive pricing, making them suitable for small workshops, warehouses, lightweight roofing systems, mezzanine floors, and auxiliary wall frames in both civil and light industrial projects.

2.2 Z Steel purlins

In contrast, Z steel purlins are preferred for larger-span and wider-bay structures. Their Z-shaped asymmetric section is specifically designed to allow lapping (overlapping joints) at supports, creating continuous beams with superior load-bearing capacity.

These purlins are precision roll-formed on automated lines, ensuring consistent size, cross-section, and thickness per project specifications. Truong Thinh produces Z purlins with:

- Height: Z120 – Z300

- Thickness: 1.8 – 3.2 mm and offers custom punching and cutting services to meet specific design requirements.

Depending on the project environment, Z purlins can be finished with industrial paint after shot blasting or hot-dip galvanizing, both of which enhance corrosion resistance and extend service life. Thanks to their lapping capability, Z purlins form continuous spans that improve load distribution and often sit directly on engineered steel frames, reducing the number of intermediate supports and columns. This design not only enhances roof stability but also saves material costs and maximizes usable space in large-scale buildings.

With excellent stiffness, high anti-deflection performance, and flexible installation, Z purlins are the optimal solution for factories, industrial warehouses, logistics centers, sports arenas, and large-span structures exposed to high wind loads.

3. Steel purlin manufacturing process at Truong Thinh Corp

The production of steel purlins at Truong Thinh Corp is carried out through a closed-loop process inside a modern, fully equipped factory. Every stage strictly complies with the ISO 9001:2015 Quality Management System, ensuring high precision, consistency, and structural integrity in each product. From material selection, slitting, roll forming (C/Z profiles), punching, cutting, surface treatment, to final inspection, all operations are PLC-automated and closely supervised by a team of experienced mechanical engineers. This enables Truong Thinh purlins to meet the rigorous technical standards required for large-scale industrial projects.

- Material selection

Truong Thinh uses only high-grade galvanized or black steel coils sourced from reputable domestic and international steel mills such as Hoa Phat (Vietnam) and POSCO (Korea), or other suppliers with verified CO/CQ certificates. Before entering production, each steel batch is tested for mechanical properties, thickness, surface finish, and coating quality to ensure compliance with design and environmental requirements. The use of premium-quality steel enhances product lifespan, minimizes deformation during roll forming, and ensures strong corrosion resistance in humid, coastal, or outdoor conditions.

- Slitting

After inspection, the steel coils are fed into an automatic slitting machine, which cuts large coils into narrower strips corresponding to the required purlin cross-section. This step demands high dimensional accuracy, as the strip width directly affects the final C or Z profile geometry. Truong Thinh’s slitting system is digitally controlled, maintaining a width tolerance of only ±1 mm while keeping the strip surface flat and free from distortion.

- Roll forming

The slit steel strips are then transferred to the automated roll forming line, where they pass through a series of precision rollers that gradually shape the metal into C or Z profiles according to design specifications.

This is the core stage of the manufacturing process, determining the accuracy, flatness, and appearance of the finished purlin. Truong Thinh’s roll forming system is PLC-controlled, ensuring stable forming speed and minimal dimensional deviation. After forming, each production batch is randomly inspected to verify key parameters such as web height, flange width, thickness, and edge squareness, ensuring compliance with technical standards.

- CNC punching (according to design requirements)

Depending on project drawings, purlins may require bolt holes at specific locations to facilitate on-site connection with rafters or bracing members. This step is performed using CNC punching machines, which guarantee precise hole positioning as per customer-provided technical drawings. The automated control and standardized die system ensure uniform hole diameters, smooth edges, and burr-free surfaces, enabling quick and safe installation at the construction site.

- Length cutting

Once punching is complete, the purlins are cut to the required lengths using CNC or plasma cutting machines. Truong Thinh can manufacture purlins up to 12 meters long, or custom lengths based on project needs. The cutting process is electronically monitored with sensors to maintain perfect squareness and minimize length deviation, reducing material waste and ensuring dimensional uniformity across structural members.

- Quality control (QC/QA)

Before delivery, every batch undergoes a comprehensive quality inspection. Truong Thinh’s QC team measures dimensions, thickness, flatness, cross-sectional accuracy, and coating quality using specialized equipment. Only products meeting all standards are packaged, labeled with identification tags, and internally approved for dispatch. Thanks to the ISO 9001:2015 quality management system, each manufacturing stage is fully traceable — from raw material input to finished product — ensuring reliability, accountability, and consistent quality for every project.

4. Steel purlin manufacturing capacity at Truong Thinh corp

Beyond meeting international material standards, Truong Thinh takes pride in its large-scale industrial production capacity, operated by a team of skilled engineers and powered by advanced, modern machinery systems.

4.1 Scale and technology

Truong Thinh Corp operates a modern steel structure and purlin manufacturing plant located in an industrial zone, covering a total area of over 25,000 m². Of this, 15,000 m² is dedicated to enclosed production workshops, while 10,000 m² serves as outdoor space for storage, assembly, and dispatch operations. This large-scale facility enables the company to execute multiple high-volume projects simultaneously, ensuring on-time delivery for both domestic and international clients.

With a monthly production capacity of approximately 1,200 tons of steel, Truong Thinh is fully capable of supplying structural components for large-scale industrial projects, including factories, warehouses, commercial buildings, infrastructure works, and export structures. All manufacturing processes are conducted under the ISO 9001:2015 Quality Management System, ensuring strict control over every stage—from material sourcing, roll forming, punching, CNC cutting, and surface treatment to final inspection and shipping.

The factory is equipped with advanced machinery and synchronized production lines, including CNC plasma cutting machines, CNC punching and drilling systems, press brakes, beam straightening machines, 3-in-1 automatic welding lines, shot blasting systems, and enclosed industrial painting booths.

All equipment is imported and operated under standardized procedures, allowing the fabrication of steel purlins and components with lengths of up to several dozen meters, achieving surface cleanliness Sa 2.5 and roughness Ra 15–50, as required by project specifications. The integration between production lines, overhead cranes, and specialized forklifts ensures efficient material handling, improved productivity, and enhanced workplace safety throughout the manufacturing process.

4.2 Engineering and quality management team

Truong Thinh’s strength lies in its team of skilled engineers, architects, and mechanical technicians with extensive experience in the design, fabrication, and erection of industrial steel structures. They are proficient in professional design and analysis software such as AutoCAD, Tekla Structures, SAP2000, and Revit, allowing for precise simulation, load calculation, and section optimization during the early design phase. Factory technicians receive regular training in CNC machinery operation, workplace safety, and product quality control, ensuring a consistent standard of workmanship.

Quality Control (QC/QA) is implemented throughout the entire production process—from raw material inspection and dimensional checks during forming and punching, to the final assessment of shape accuracy, thickness, flatness, and coating quality before shipment. All results are recorded in Truong Thinh’s internal management system, providing full traceability for each production batch, along with inspection reports and quality certificates delivered to clients.

4.3 Certifications and quality standards

All manufacturing activities at Truong Thinh Corp are operated in accordance with the ISO 9001:2015 Quality Management System, officially audited and certified by accredited authorities. This certification ensures consistency, transparency, and reliability throughout the entire production cycle — from material preparation and machine operation to final product inspection — guaranteeing that every purlin and steel component meets the highest industrial and export quality standards.

5. Our featured projects

Over more than 18 years of development, Truong Thinh Corp has partnered with hundreds of domestic and international investors, delivering numerous landmark industrial projects. Below are two outstanding examples that highlight our technical strength and execution capacity:

5.1. Royal house brick manufacturing plant – Nhon Trach II industrial zone

- Location: Nhon Trach II Industrial Zone – Nhon Phu, Dong Nai

- Investor: Royal Group

- Construction period: 12 months

- Scope of work: Demolition of the existing factory and construction of a new production facility

- Project overview:

The Royal House Brick Manufacturing Plant is a signature industrial project executed by Truong Thinh Corp under a turnkey contract. The large-scale project includes a 30×54 m raw material warehouse (1,620 m²), a two-story warehouse measuring 30×74.4 m (4,464 m²), and a 30×40 m main production hall (1,200 m²).

All steel framing, purlins, and load-bearing structures were designed according to heavy industrial standards to ensure machinery load capacity and operational safety. Truong Thinh was responsible for dismantling the old factory, constructing the new steel structure, roofing, wall cladding, and completing the technical infrastructure — all while ensuring strict adherence to the Royal Group’s quality and schedule requirements.

5.2. High-Tech Shrimp Breeding Farm – Ninh Thuan Province

- Location: Hoa Thanh – An Hai – Ninh Phuoc – Ninh Thuan

- Main contractor: Truong Thinh Construction and Trading Investment JSC

- Construction period: 2023

- Scope of work: Construction of staff accommodation, canteen, office building, and broodstock shrimp facility

- Project overview:

The High-Tech Shrimp Breeding Farm in Ninh Thuan is one of Vietnam’s most advanced aquaculture facilities to date. As the main contractor, Truong Thinh Corp handled every phase of the project — from structural design and steel frame fabrication to the completion of supporting facilities such as office buildings, staff quarters, canteen, and the broodstock shrimp breeding area.

The project was designed as a closed-loop shrimp farm, meeting stringent biosecurity, temperature, and humidity control standards while optimizing functionality. Considering Ninh Thuan’s challenging coastal climate, Truong Thinh implemented lightweight materials, galvanized steel framing, and advanced insulation systems to enhance durability, reduce maintenance costs, and extend the building’s lifespan. This project not only supports the growth of Vietnam’s high-tech aquaculture industry but also showcases Truong Thinh’s professional expertise in specialized industrial construction.

6. Why choose steel purlins from Truong Thinh corp?

In the field of steel structure manufacturing and construction, Truong Thinh Corp has established a solid reputation built on superior production capacity, strict quality control, and professional service. Choosing Truong Thinh’s steel purlins means more than just technical reliability — it ensures cost efficiency, timely delivery, and long-term peace of mind for investors, contractors, and design consultants.

- Exceptional quality – ISO 9001:2015 certified products

All Truong Thinh purlins are manufactured under the ISO 9001:2015 quality management system, certified and audited by accredited authorities. Every production stage — from raw material selection, cold-forming, punching, and CNC cutting to surface treatment — is closely monitored by a dedicated QC/QA team to ensure compliance with international technical standards.

- High production capacity – Meeting large-scale project deadlines

With a 25,000 m² manufacturing facility, including 15,000 m² of enclosed workshop space, Truong Thinh is fully equipped to handle large-scale domestic and export projects on schedule. The plant operates at an average capacity of 1,200 tons per month, powered by modern equipment such as CNC plasma cutting systems, CNC drilling/punching machines, automatic cold-forming lines, bending machines, beam straighteners, 3-in-1 welding systems, and Sa 2.5-grade shot blasting and painting booths. This synchronized production system enables precise fabrication of C and Z purlins with flexible lengths, accurate dimensions, and surface finishing that meet international technical standards.

- Experienced engineering team – Supporting clients from design to construction

Truong Thinh’s team of engineers, architects, and mechanical technicians are well-trained and highly experienced in the industrial steel structure sector. Proficient in technical software such as AutoCAD, Tekla Structures, and SAP2000, they assist clients throughout every project phase — from load analysis and purlin section optimization to material and coating selection tailored to each project’s environment.

Our QC/QA team works hand-in-hand with production staff to ensure continuous quality assurance at every stage. This strong combination of technical expertise and practical experience enables Truong Thinh to deliver not just products, but complete and cost-efficient structural solutions.

- Competitive pricing – Direct from the manufacturer

As a direct manufacturer, Truong Thinh maintains full control over sourcing, design, and production — eliminating intermediaries and offering clients high-quality products at factory prices. Our pricing policy is transparent and clearly itemized according to volume, specifications, and technical requirements, helping customers plan budgets accurately from the early project stages.

- After-Sales service and warranty – Long-term partnership commitment

Beyond production and delivery, Truong Thinh provides comprehensive after-sales and technical support. Each project includes a clear, contract-based warranty policy, covering structural inspection, repair or replacement of any manufacturing defects, and technical consultation during installation. This customer-first approach underscores Truong Thinh’s long-term commitment to reliability, service, and sustainable value for every client.

7. Collaboration process with Truong Thinh corp

To ensure every project is executed efficiently, transparently, and to the highest standards, Truong Thinh Corp has established a five-step collaboration process that tightly integrates technical consulting, manufacturing, construction, and handover. This closed-loop workflow not only enables clients to easily track progress but also helps shorten project timelines by 20–30% compared to traditional methods, while maintaining full compliance with ISO quality standards.

Step 1: Requirement assessment & technical consultation

Upon receiving project information, Truong Thinh’s technical department conducts a detailed analysis of parameters such as scale, load capacity, site conditions, budget, and desired schedule. Based on these inputs, our engineering team proposes an optimized structural solution complete with preliminary drawings, cost estimates, and technical recommendations. This step provides investors with a clear overview of the project’s design direction and initial investment requirements before moving forward.

Step 2: Site Survey & detailed design

Once both parties agree on the overall solution, Truong Thinh’s survey team visits the construction site to collect key data — elevation, soil characteristics, erection space, and environmental conditions. These measurements are then processed using Tekla Structures, SAP2000, and AutoCAD 3D, enabling precise digital modeling with a tolerance of ±1 mm. The final design drawings go through an internal QC checklist before being submitted for client approval, ensuring technical feasibility and full compliance with industry standards.

Step 3: Manufacturing at Truong Thinh factory

After design approval, production begins at Truong Thinh’s manufacturing facility in Binh Duong. All materials — including galvanized or black steel coils and accessories — come with full CO/CQ certifications and conform to international standards such as ASTM and JIS. Cutting, welding, and surface treatment are performed on a fully automated 3-in-1 production line, guaranteeing precision and consistency across all components.

After welding, the steel surfaces are shot-blasted to Sa 2.5, followed by three-layer epoxy coating or hot-dip galvanizing, depending on project requirements. Each finished product is assigned a unique QR code for complete traceability — including batch number, specifications, and inspection history — ensuring transparency and ease of quality verification.

Step 4: Delivery, erection & handover

Once fabrication is complete, components are packaged and delivered using certified 20–50 ton cranes and transport trucks, meeting safety standards issued by the Ministry of Labor, Invalids, and Social Affairs. Truong Thinh’s experienced erection team directly handles on-site installation, coordinating with the main contractor to ensure on-time delivery and strict adherence to safety protocols. The entire project undergoes load testing, quality inspection, and ISO 9001:2015 compliance verification before final handover to the client.

8. After-sales service

Steel purlins remain one of the most efficient and durable structural options for industrial facilities requiring high load capacity, fast installation, and long-term cost optimization. At Truong Thinh Corp, we combine engineering expertise, precision manufacturing, and rigorous quality control to deliver products that meet every technical and schedule requirement.

If you are a contractor, engineer, or project owner looking for reliable roofing or structural solutions, Truong Thinh’s C and Z steel purlins deliver the ideal balance of strength, efficiency, and cost-effectiveness. For detailed quotations or technical consultations, our team is always ready to support you — Contact us today to get started.