High Quality Steel Frames Supplier and Manufacturer

In the rapid development of industrial and civil construction, steel frames have become the preferred choice thanks to their durability, superior load-bearing capacity, and cost-effectiveness during installation. With over 18 years of experience, Truong Thinh is proud to be one of Vietnam’s leading manufacturers and suppliers of steel structures. Beyond serving the domestic market, we have expanded our partnerships across Southeast Asia, including Indonesia, Thailand, the Philippines, and Malaysia, delivering high-quality steel frame products for large-scale international projects.

1. Steel frame production process at Truong Thinh’s factory

At Truong Thinh, the steel frame production process is fully integrated from design, fabrication, and welding to surface treatment and final inspection before delivery. Each stage is strictly monitored by our team of engineers and QC department to ensure products meet international standards.

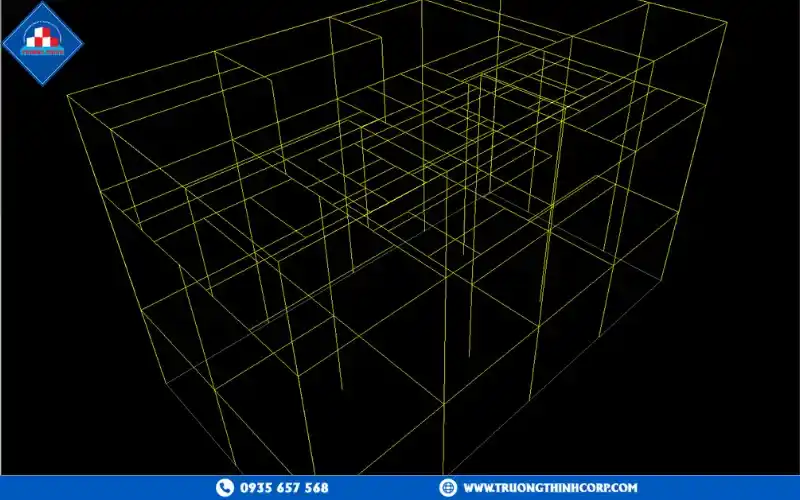

1.1. Stage 1: Design

The design phase plays a vital role in ensuring that steel frames are both structurally efficient and cost-effective. Our experienced engineers use advanced software such as Tekla Structures, SAP2000, and AutoCAD 3D to simulate the entire roof structure, defining precise angles, spans, and connection points — including recommended spacing and bearing details for steel purlin to ensure correct load transfer between roofing and the main truss.

Each drawing undergoes cross-verification between structural and production departments to guarantee consistency in dimensions, loads, and materials. This process ensures that the final product is lightweight yet durable, suitable for a variety of applications including industrial plants, dome roofs, showrooms, and large-scale civil structures.

1.2. Stage 2: Fabrication – CNC cutting, punching, and welding

During fabrication, all incoming steel materials are strictly inspected and certified (CO/CQ). Our facility is equipped with CNC plasma cutting machines, CNC drilling-punching systems, and 3-in-1 automatic horizontal welding lines that ensure near-perfect precision for each component.

All welds are executed using SAW and FCAW CO₂ technologies according to AWS D1.1 standards, ensuring exceptional strength, appearance, and load capacity. Automated production lines maintain tolerances within ±1–2 mm, enabling flawless assembly at the construction site.

1.3. Stage 3: Finishing and surface protection

After fabrication, steel frames undergo surface treatment through automatic shot blasting (Sa2.5 standard) to remove impurities, rust, and create optimal adhesion for coatings. Depending on the project requirements, Truong Thinh applies appropriate surface protection methods:

- Epoxy primer (50–75 µm) + Polyurethane topcoat (40–60 µm) for standard projects.

- Hot-dip galvanizing (70–100 µm) for coastal or high-humidity environments.

Thanks to these treatments, Truong Thinh steel frames maintain their strength and shape for 20–50 years, even under extreme weather conditions.

2. Truong Thinh ’s steel frame manufacturing capacity

Behind every product is a fully equipped factory, cutting-edge technology, and a professional engineering team. We continuously invest in advanced technology and management systems to ensure productivity, precision, and on-time delivery for every project.

2.1. Scale and technology

Our steel structure plant spans 25,000 m², including 15,000 m² of enclosed workshops and 10,000 m² for storage, offices, and logistics. The entire production line features CNC cutting machines, 3D drilling machines, automatic welding systems, shot blasting chambers, industrial painting booths, and 5–20 ton overhead cranes. Our production capacity reaches 1,500 tons per month, meeting both domestic and export demands.

2.2. Engineering and QC team

Our engineers have extensive experience in designing and fabricating various truss systems such as W-trusses, Pratt, Howe, and steel truss structures, ensuring that each product meets the highest standards of safety and performance. Each order undergoes rigorous inspection of dimensions, load capacity, welds, and coating thickness by a dedicated QC team to ensure every product meets safety and performance standards.

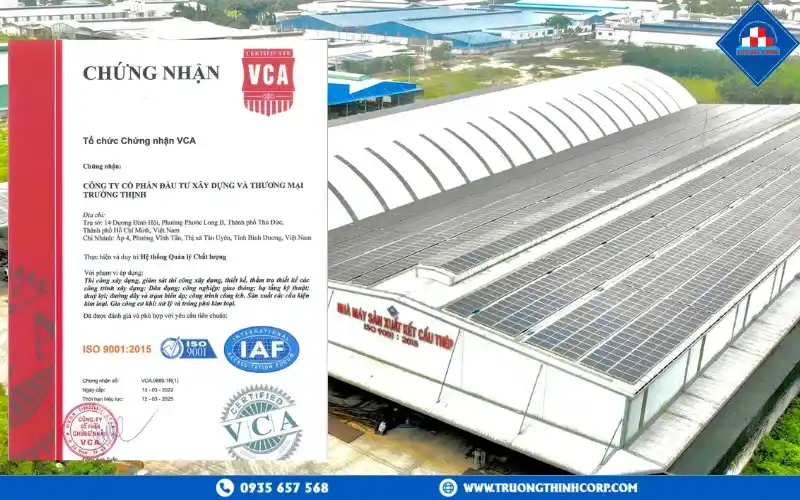

2.3. Certifications and standards

Truong Thinh steel frames are manufactured in compliance with ASTM 3834, JIS/J3101, or EN 1090 standards, depending on project requirements. Every batch includes CO/CQ documentation and inspection certificates, ensuring transparency and traceability.

3. Truong Thinh’s steel frame standards

We adhere strictly to international standards in material selection, fabrication, and surface treatment to guarantee product durability and structural longevity. Each component is designed to match specific load, climate, and usage conditions, especially in large-span roof systems that utilize a frame of steel truss for enhanced strength and architectural flexibility.

3.1. Materials and steel grades

Truong Thinh uses only high-quality steel:

- SS400 / Q235 / A36 for light and medium-load trusses.

- Q355 / A572 for large-span, heavy-duty trusses.

All materials are tested for mechanical properties, certified for origin, and compliant with global engineering standards.

3.2. Dimensions and specifications

We can fabricate trusses based on custom designs or standard specifications, with material thickness ranging from 6–40 mm and maximum member length up to 15,000 mm. A machining tolerance of ±1 mm ensures perfect alignment during assembly, minimizing on-site deviations.

3.3. Strength and testing

All products are analyzed for axial compression, bending moments, tensile strength, and torsional resistance according to design codes. Components are tested for mechanical performance, ultrasonic weld inspection, and coating thickness before delivery to guarantee strength and safety.

3.4. Surface treatment

Steel frames are protected with epoxy primer or hot-dip galvanizing, enhancing corrosion resistance and extending service life. Galvanized coatings (70–100 µm) provide durability of 20–50 years in standard environments and 10–20 years in coastal regions.

4. Featured projects

Truong Thinh’s steel frames are consistently recognized for engineering quality, structural strength, and construction efficiency. The following key projects showcase our manufacturing and installation capabilities, solidifying our reputation in both industrial and civil steel structure sectors.

4.1. Dak Tih Hydropower Plant – Dak Nong province

- Location: Gia Nghia City, Dak Nong Province

- Investment: Over VND 5,000 billion

- Scope: Fabrication, supply, and installation of structural roof trusses for the lower-level plant, distribution station, and upper spillway.

This project required exceptional anti-vibration, humidity resistance, and wind-load performance. The W-type trusses, fabricated from Q355 hot-dip galvanized steel and assembled with Grade 8.8 high-strength bolts, achieved CNC precision within ±1 mm, reducing erection time by 20%. The 100 µm zinc coating ensures durability exceeding 40 years in high-humidity mountain climates.

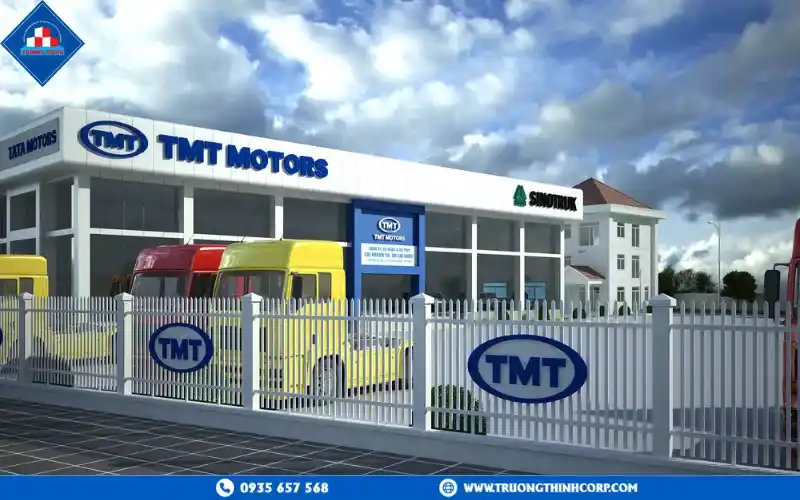

4.2. TMT Southern Auto Showroom – Binh Duong province

- Location: Di An City, Binh Duong

- Type: Automobile showroom with integrated service center

- Scope: Design, fabrication, and installation of the entire roof truss and spatial frame system.

Featuring large spans (24–30 m) and a modern architectural aesthetic, the project was modeled using Tekla Structures 3D BIM, ensuring seamless integration between steel frames, composite roofing, and interior systems. The lightweight Pratt Truss system was fabricated from SS400 steel with a two-layer epoxy coating, balancing load-bearing strength and visual elegance. Automated SAW/FCAW CO₂ welding ensured perfect alignment and completion 15 days ahead of schedule.

4.3. Phnom Penh Commercial Center – Cambodia

- Location: Phnom Penh Capital, Cambodia

- Type: Shopping mall and office complex

- Scope: Design, fabrication, and supply of roof trusses, steel frames, and large-span beams.

The project required 25–35 m spans and high structural accuracy. Using Tekla BIM 3D modeling, Truong Thinh ensured perfect coordination between truss systems, composite roofing, and architectural components.

Trusses were fabricated from Q355/A572 steel, shot-blasted to Sa2.5, and coated with epoxy–polyurethane layers, enhancing corrosion and moisture resistance under tropical conditions. All components were packaged and transported by land to Cambodia, ensuring international standards of quality and delivery.

Beyond these key projects, Truong Thinh has been a trusted partner in hundreds of industrial, commercial, and infrastructure projects across Vietnam. We also fabricate and export steel structures and trusses to Indonesia, Thailand, the Philippines, Malaysia, Singapore, Myanmar, Cambodia, Laos, and Australia.

5. Our collaboration process

At Truong Thinh, every project follows a comprehensive, transparent, and efficient workflow—ensuring optimal quality, schedule, and cost control.

Step 1: Requirement analysis and technical consultation

Upon receiving client inquiries, our engineers and consultants analyze the project’s design intent, usage goals, and budget. Based on this data, we propose the most efficient structural steel solutions that balance strength, aesthetics, and cost.

Step 2: Site survey and technical design

After preliminary approval, our team conducts detailed site surveys for terrain, soil, and construction conditions. Using Tekla, SAP2000, and AutoCAD 3D, we simulate and calculate precise dimensions and connection details. Final drawings are submitted to the client for review before production begins.

Step 3: Fabrication at the factory

Once designs are approved, fabrication proceeds on our automated CNC lines, compliant with ISO 9001:2015 standards. QC inspections verify every aspect—from dimensions and welds to coating thickness and documentation—before shipment.

Step 4: Installation and handover

At the site, assembly follows strict installation protocols with ±1 mm tolerance accuracy. Our construction team upholds rigorous safety and progress standards, ensuring timely and high-quality project completion. Before handover, the project undergoes a full inspection, accompanied by as-built documents, CO/CQ certificates, and a 12-month warranty.

6. After-sales service and technical support

Post-handover, Truong Thinh continues to support clients with technical assistance, maintenance, and structural optimization consultation. Our engineers remain ready to adjust designs or recommend improvements based on real-world operation. We provide a 12-month warranty for main structural components, extendable per contract, ensuring complete customer confidence in our quality and service.

With modern technology, advanced production systems, and a highly skilled team, Truong Thinh is not only a trusted Vietnamese steel frame manufacturer but also a strategic partner across Southeast Asia — including Indonesia, Thailand, the Philippines, Malaysia, and Singapore. We are dedicated to providing optimized, high-quality, and sustainable steel structure solutions that help shape the future of the construction industry. Contact us to explore collaboration opportunities or get tailored solutions for your project.