High Quality Steel Column Manufacturer And Supplier

In modern construction projects, steel columns play a crucial role in creating a strong and stable framework that ensures structural integrity and long-term durability. Thanks to their exceptional load-bearing capacity, high strength, and flexible fabrication, steel columns have become the preferred choice for factories, industrial facilities, and high-rise buildings. With advanced technology and a team of skilled engineers, Truong Thinh proudly stands as a leading manufacturer and supplier of international-standard steel columns, delivering optimal structural solutions that fully meet technical requirements and project timelines for both domestic and international markets.

1. Steel column manufacturing standards

To ensure maximum quality and service life for every structure, Truong Thinh strictly adheres to international standards regarding materials, mechanical properties, load capacity, and surface treatment.

Steel columns are manufactured using materials such as SS400, Q235, Q345B, or A572, depending on project load requirements and scale. Each material comes with a mechanical test certificate (tensile strength ≥ 400 MPa, yield strength ≥ 235 MPa) and undergoes detailed chemical composition inspection prior to production.

Columns can be fabricated according to custom drawings or standard specifications, with heights ranging from 3,000 – 15,000 mm, thicknesses 6 – 60 mm, and cross-sections including H, I, Box, or Pipe profiles.

Before delivery, each column is subjected to compressive load tests, bending moment tests, and stability verification to ensure compliance with design load capacities.

2. Steel column manufacturing process

At Truong Thinh, the manufacturing process is highly automated and closed-loop, comprising five key stages: design – fabrication – welding – surface treatment – final inspection. Every step is supervised by skilled structural engineers and the Quality Control (QC) team to ensure compliance with international standards.

2.1. Stage 1: Design and structural analysis

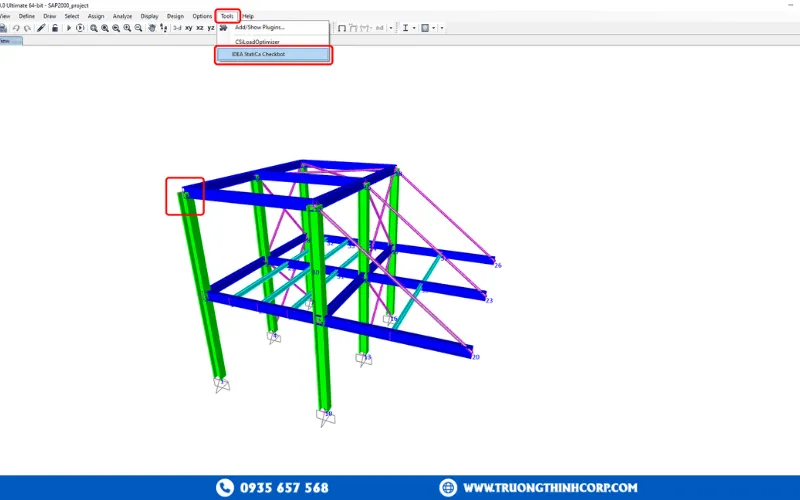

Design is the most critical stage, determining load-bearing capacity and material efficiency. Our engineers utilize advanced software such as Tekla Structures, SAP2000, and AutoCAD 3D to model entire structures, precisely calculating axial loads, bending moments, stability, and foundation conditions.

Each drawing is carefully reviewed by both the design and production departments to ensure complete consistency between the design phase and actual construction. Using 3D modeling, all components such as connection plates, steel base column, and anchor bolts are precisely detailed, reducing the risk of assembly errors on site.

This meticulous process allows Truong Thinh’s products to meet strict technical standards while optimizing cost, weight, and construction time, making them an ideal choice for factories, warehouses, high-rise buildings, showrooms, and commercial centers.

2.2. Stage 2: CNC cutting, drilling, and automated welding

Once the drawings are approved, all incoming raw steel materials are inspected for mechanical properties and certified with CO/CQ documentation.

We continuously invest in modern machinery such as 6–12m CNC Plasma & Oxy-gas cutting systems, 3D CNC drilling machines, automatic beam straighteners, and 3-in-1 welding lines, ensuring near-perfect precision. SAW and FCAW CO₂ welding technologies are performed in accordance with AWS D1.1 standards, producing uniform, strong, and visually clean welds. This same high-precision approach is applied in the fabrication of gusset plates for structural connections.

Automation keeps production tolerance within ±1 mm, ensuring perfect alignment during installation. All welds are tested using Ultrasonic Testing (UT) and Magnetic Particle Testing (MT) to detect internal defects and guarantee superior safety and longevity.

2.3. Stage 3: Finishing and surface protection

After structural completion, components undergo shot blasting to achieve a cleanliness grade of Sa2.5, removing all impurities, rust, and oil to ensure optimal adhesion for paint or galvanizing.

Depending on project requirements, Truong Thinh offers two surface protection methods:

- Epoxy primer + Polyurethane coating – suitable for indoor or dry environments.

- Hot-Dip Galvanizing (HDG) – ideal for coastal or high-humidity areas.

The 70–100 µm zinc coating provides effective corrosion resistance, ensuring a service life of 30–50 years under normal conditions and around 20 years in coastal environments.

Before shipment, all components are inspected for coating thickness, adhesion, and surface appearance to guarantee quality and durability.

3. Truong Thinh’s steel column production capacity

Behind every high-standard product is a foundation of robust manufacturing capacity, strict quality management, and strong technical expertise.

3.1. Factory scale and technology

Truong Thinh’s steel structure plant spans over 25,000 m², including production zones, warehouses, and offices. Equipped with a modern CNC production line and a monthly output of 1,200–1,500 tons, we can efficiently meet domestic and Southeast Asian export demands.

3.2. Engineering and quality control team

Our team of structural engineers and QC specialists has extensive experience in heavy steel structure design, fabrication, and testing. Each product undergoes meticulous inspection—from dimensions, weld quality, and coating to mechanical properties—with complete technical documentation and CO/CQ certificates provided to clients.

3.3. Certifications and quality standards

Truong Thinh steel columns comply with the following international standards:

- ISO 9001:2015 – Quality Management System

- ASTM A36, JIS G3101, EN 1090 – Material and fabrication standards

- AWS D1.1 – Structural welding standard

- CO/CQ – Certificates of Origin and Quality

By integrating these global standards, Truong Thinh consistently delivers products that meet rigorous technical and inspection requirements for both domestic and international projects.

4. Featured projects

Truong Thinh has supplied steel columns for hundreds of large-scale projects both in Vietnam and overseas. Below are several notable projects that showcase our expertise and reliability.

4.1. DABACO animal feed factory – Binh Phuoc

- Location: Binh Phuoc Province, Vietnam

- Type: Industrial-scale animal feed factory

- Scope: Fabrication and supply of H600 load-bearing columns and main trusses

With a total area exceeding 20,000 m², the project required high-load capacity and structural stability. Despite challenging site conditions and tight deadlines, Truong Thinh operated CNC production across three shifts, completing the project 15 days ahead of schedule. All columns were fabricated using Q345-grade steel, fully tested for bending moment and compressive strength prior to delivery, ensuring absolute precision and quality.

4.2. Dami Gia hotel – Vinpearl Nha Trang

- Location: Vinpearl Resort Complex, Nha Trang, Vietnam

- Type: Luxury beachfront hotel

- Scope: Fabrication and installation of central load-bearing steel columns

As part of the Vinpearl complex, Dami Gia Hotel required structurally complex and visually refined components. Truong Thinh supplied main load-bearing columns designed to withstand wind, vertical, and lateral loads per international standards.

All components were coated with two layers of epoxy and a polyurethane UV-resistant finish, ensuring long-lasting protection in marine climates. The project was completed on schedule, enhancing Vinpearl’s modern architectural appeal and reaffirming Truong Thinh’s capability in high-rise coastal projects.

5. Cooperation process

Each Truong Thinh project follows a streamlined process designed to optimize quality, cost, and timeline:

- Requirement analysis & consultation: Our engineers assess project goals, budget, and technical demands to propose the most efficient and cost-effective steel structure solution.

- Site survey & technical design: Using Tekla Structures, SAP2000, and AutoCAD 3D, we conduct detailed structural modeling and load analysis for precise fabrication.

- Factory production: All components are produced on our automated CNC line under ISO 9001:2015, with full QC inspection and certification before dispatch.

- Installation & handover: On-site assembly follows strict safety and accuracy standards (tolerance ±1 mm). The project is delivered with full documentation, CO/CQ certificates, and a 12-month warranty.

6. Pricing and payment terms

Transparent pricing: Clear unit pricing or flexible quotation based on dimensions, specifications, and surface finishing (paint or galvanizing). Bulk orders receive competitive discounts.

Payment terms: Standard international methods – including advance payment upon contract signing, progress payments, and L/C or bank transfer options.

Additional costs:

- Transportation: Calculated by actual weight (20–30 tons/truck).

- Installation: Based on volume, complexity, and site safety conditions. Truong Thinh guarantees no hidden costs—all adjustments are mutually approved in advance.

7. After-sales service and warranty

All steel column products are covered by a 12-month warranty for main structures, with optional extensions depending on project scale. Even after handover, Truong Thinh continues to support clients through technical assistance, maintenance, and structural optimization consulting—ensuring lasting reliability and client satisfaction.

With modern technology, advanced production systems, and a highly skilled team, Truong Thinh Corp stands as not only a trusted Vietnamese steel column manufacturer but also a strategic partner across Southeast Asia. We are committed to providing optimized, high-quality, and sustainable steel column solutions that drive the modernization of the industrial construction sector. Contact us to learn more about our products or discuss your upcoming project.