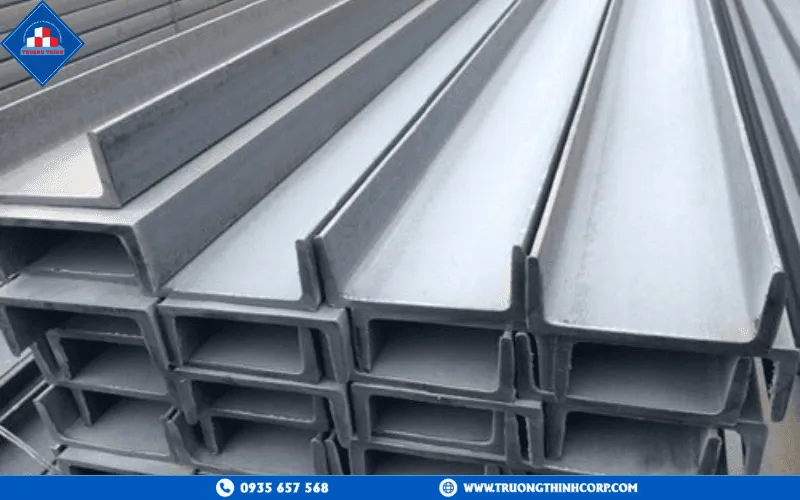

Factory Producing Steel Beams On Demand

In modern industrial and civil construction, steel beams serve as the backbone of the entire structural system, determining a project’s strength, stability, and aesthetics. With nearly 20 years of experience, Truong Thinh stands as a pioneer in the design and fabrication of high-performance steel beams, delivering optimal, sustainable, and cost-efficient roof and frame solutions for hundreds of domestic and international projects.

1. Advantages of steel beam over reinforced concrete beams

While reinforced concrete has long been a traditional material, steel beams are increasingly favored for their high load-bearing capacity, lightweight design, flexibility in architecture, and long service life. Their quick installation and low life-cycle cost make them a modern, efficient, and durable structural solution for diverse construction applications.

1.1 Load-bearing capacity

Truong Thinh steel beams are fabricated from SS400 / Q235 / A36 or Q355 / A572 steel grades, offering tensile strengths up to 510 MPa and minimum yield strengths of 235 MPa, equivalent to ASTM A36 or JIS G3101 standards. Thanks to their superior mechanical properties, these beams efficiently resist axial, bending, and torsional loads. Certain profiles, such as our engineered H-beam, are specifically optimized for high compressive and bending performance in wide-span industrial structures. Each beam undergoes HRC load testing to ensure long-term elasticity and structural stability.

1.2 Weight efficiency

Steel beams are 30 to 50 percent lighter than reinforced concrete, which helps reduce foundation loads, save construction materials, and shorten project timelines. Their lightweight nature also makes transportation, lifting, and on-site assembly more convenient and safer, while maintaining the overall durability of the structure.

1.3 Fabrication and installation

All steel beams are pre-fabricated at Truong Thinh’s factory to ensure high precision in every component before installation. Each piece is cut, welded, and inspected using automated technology, minimizing risks and errors during on-site work. The assembly process is quick and efficient, requiring only a small technical team to complete the steel frame within a short timeframe.

1.4 Flexibility in design

One of the greatest advantages of steel beams is their versatility in dimensions, profiles, and shapes to suit specific project requirements. For wide-span roofs and architectural solutions that require both light weight and structural clarity, Truong Thinh also provides factory-manufactured steel truss systems that complement beam designs, allowing easier expansion, reuse, and reduced life-cycle costs during renovation or dismantling.

1.5 Life-cycle cost

Although initial investment in steel beams may be higher than concrete, their maintenance and operational costs are much lower. With a lifespan of 40–50 years (depending on coating or galvanizing methods), the total life-cycle cost of steel beams is 20–30% lower than that of conventional materials.

1.6 Fire resistance

Truong Thinh’s steel beams are coated with fire-resistant and multi-layer epoxy paint to protect against high temperatures and corrosion. The coating thickness ranges from 50–75 µm per layer, totaling 100–200 µm, enhancing fire resistance and durability even under Vietnam’s harsh climatic conditions.

2. Steel beam manufacturing process at Truong Thinh factory

At Truong Thinh, every steel beam is produced through a closed and standardized process that covers design, fabrication, welding, surface treatment, and final quality inspection. The entire operation is managed under the ISO 9001:2015 quality management system to ensure precision, consistency, and durability in every product before it is delivered to clients.

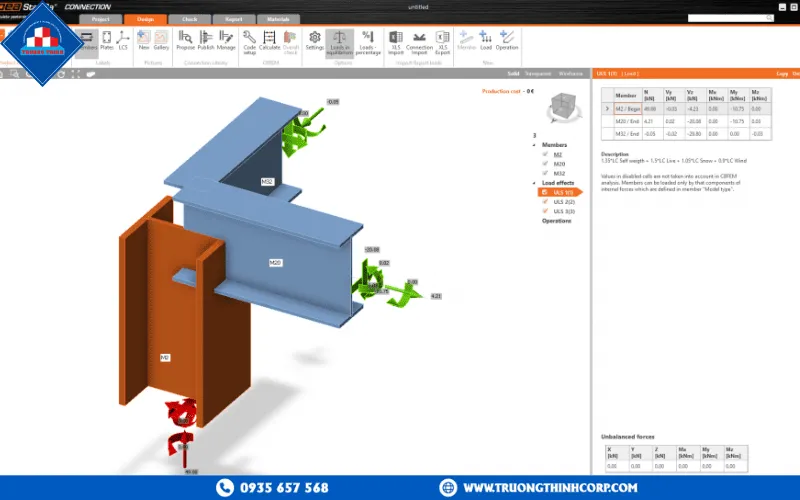

2.1 Stage 1: Design

At the initial stage, our engineering team employs advanced software such as Tekla Structures, SAP2000, and AutoCAD to create 3D models and precisely calculate load-bearing capacities for each structural component.

Every drawing undergoes cross-checking between the design engineers and the production department to guarantee complete alignment between the model and the actual fabrication. This rigorous verification process eliminates errors, optimizes steel weight, and helps reduce material costs for clients.

2.2 Stage 2: Automated cutting and welding

In our factory, fabrication is carried out using CNC plasma or laser cutting machines with an accuracy of plus or minus 1 millimeter. For certain structural profiles, especially our fabricated I-beam lines, beams move through automatic gantry welding and integrated welding cells to ensure deep penetration and uniform seams in full compliance with JIS Z 3801.

All raw materials come with CO and CQ certificates verifying their origin and quality, and are mechanically tested prior to production. The automated welding system significantly minimizes human error, boosts productivity, and ensures consistency across all finished products.

2.3 Stage 3: Surface finishing and protection

After welding, the beam surfaces are shot-blasted to the Sa 2.5 standard, achieving a roughness of Ra 15–50 µm for optimal paint adhesion. Depending on project requirements, Truong Thinh applies either a three-layer epoxy anti-corrosion coating or hot-dip galvanization.

The epoxy coating offers superior adhesion, resistance to UV rays, chemicals, and marine humidity, with an average thickness of 100–200 µm. For galvanized beams, the zinc layer ranges from 80–120 µm, providing 10–20 years of corrosion resistance even in outdoor or coastal environments. All products undergo strict thickness and adhesion testing before leaving the factory to ensure long-lasting performance and surface quality.

3. Steel beam manufacturing capacity at Truong Thinh Corp

Beyond meeting international material standards, Truong Thinh takes pride in its large-scale industrial production capacity, operated by a team of skilled engineers and powered by advanced, modern machinery systems.

3.1 Scale and technology

Located in Tan Uyen, Binh Duong, the Truong Thinh factory covers an area of over 25,000 m², including 15,000 m² of production workshops and 10,000 m² of outdoor storage space. The production line is fully equipped with CNC cutting machines, automated welding gantries, 3D drilling systems, beam straightening machines, shot blasting equipment, and modern paint booths. With an average output of 1,200–1,500 tons per month, Truong Thinh ensures timely delivery for both domestic and export projects.

3.2 Engineering team and quality management

Truong Thinh currently employs more than 680 staff members, including structural engineers, technicians, and certified welders. Each stage of production is monitored by an independent QA/QC department, ensuring that all steel beams are meticulously inspected for dimensional accuracy, flatness, weld integrity, and coating quality. Thanks to its rigorous internal quality control system, Truong Thinh maintains an output defect rate below 1%, reinforcing its reputation for reliability and precision.

3.3 Certifications and quality standards

All Truong Thinh products are certified under ISO 9001:2015, with complete CO-CQ documentation for every batch of material. Manufacturing processes strictly comply with ASTM 3844, JIS G3101, and EN 1090 standards, ensuring full compatibility with the requirements of high-demand export markets such as Japan, South Korea, and Europe.

4. Truong Thinh’s steel beam manufacturing standards

Truong Thinh’s steel beams are fabricated from high-strength low-alloy steel (Carbon or HRC), with chemical composition periodically inspected and verified. Each product is manufactured in lengths ranging from 4 to 15 meters, with web heights of 300–1,500 mm, flange widths of 150–500 mm, and plate thicknesses of 5–20 mm, making them suitable for most types of industrial building structures.

All beams undergo mechanical property testing and load-bearing assessments, including bending and torsion tests. Results consistently show that Truong Thinh’s steel beams achieve an average yield strength of 235 MPa and a tensile strength of 400–510 MPa, ensuring safety and stability under heavy loads or harsh environmental conditions.

The beam surfaces are finished with either epoxy coating or hot-dip galvanization, with a coating thickness of 100–200 µm for epoxy paint and 80–120 µm for zinc plating. Each product is designed for a service life of 40–50 years, backed by a 12-month structural warranty and lifetime technical support, reaffirming Truong Thinh’s commitment to long-term durability and customer satisfaction.

5. Our featured projects

With more than 18 years of development, Truong Thinh has partnered with hundreds of domestic and international investors, successfully delivering a wide range of projects including large industrial plants, logistics cold storage facilities, and high-end residential villas. Below are two of our most notable projects.

5.1 Phan Duy Cold Storage Complex – Cold Warehouse & Supporting Infrastructure

- Location: Nhut Chanh industrial park, Long An province

- Scale: 60,000 m² (including over 20,000 m² of transport yard and cargo staging area)

- Completion year: 2016

- Scope of work: Construction of internal road systems, water supply and drainage networks, and cargo yard infrastructure

- Project description:

The Phan Duy Cold Storage Complex is a modern logistics facility combining both cold and dry storage areas, designed to support large-scale goods preservation and distribution.

In this project, Truong Thinh was responsible for the entire technical infrastructure, including internal roads, water supply and drainage systems, rainwater and wastewater management, as well as the transport yard and container staging zones.

5.2 Khang Dien Residential Villa – Premium Private Villa Project

- Location: District 9, Ho Chi Minh City

- Scale: 350 m²

- Completion Year: 2017

- Scope of Work: Structural design and construction

- Project description:

The Khang Dien Villa is a high-end residential project that demands exceptional precision in both architectural design and structural execution. Truong Thinh took charge of structural design, technical consulting, and construction of all load-bearing components.

Our team of engineers and architects worked closely to achieve a perfect balance between aesthetics and functionality. They optimized the load-bearing frame, structural layout, and component connections to ensure both superior durability and architectural elegance.

6. Why choose steel beam from Truong Thinh

Customers choose Truong Thinh’s steel beams not only for their superior material quality but also for the company’s comprehensive service ecosystem, which covers every stage from design, production, and transportation to warranty and technical support. Truong Thinh is more than a steel structure manufacturer. We are a trusted technical partner who accompanies investors through every phase of their project.

First and foremost, material quality is absolutely guaranteed. Truong Thinh uses Q355 / A572, SS400 / Q235 / A36 steel grades, meeting ASTM A36, JIS G3101, and EN 1090 standards. Each batch of raw material is verified with CO–CQ certificates and mechanical testing on HRC equipment.

As a result, our steel beams consistently achieve a minimum yield strength of 235 MPa and tensile strength between 400–510 MPa, ensuring reliable resistance to bending, torsion, and compression loads in large-scale projects such as factories, cold storage facilities, logistics centers, and multi-story commercial buildings.

Another key advantage is our industrial-scale production capacity. Our 25,000 m² factory is equipped with CNC Plasma cutting systems, 3-in-1 automatic welding machines, 3D drilling units, and electrostatic painting booths. With an average capacity of 1,200–1,500 tons of steel per month, Truong Thinh can simultaneously meet the demands of multiple domestic and international projects with consistent quality and timely delivery.

Our team of more than 680 engineers, QC/QA specialists, and skilled technicians maintains strict quality control at every stage, from design and fabrication to on-site acceptance testing. With this closed-loop management system, Truong Thinh keeps its output defect rate below 1 percent, which is significantly lower than the industry average.

Finally, Truong Thinh emphasizes transparent after-sales service and long-term commitments. All products come with a 12-month structural warranty and dedicated project records. Our technical team is always ready to provide on-site support for any structural adjustments, repairs, or re-inspections, ensuring complete peace of mind for every client.

7. Our collaboration process

To ensure every project is executed efficiently, transparently, and on schedule, Truong Thinh has developed a five-step closed-loop collaboration process that connects our engineering, production, and client teams seamlessly. This process not only strengthens quality control but also helps shorten average delivery time by 20–30% compared to conventional construction methods.

Step 1: Requirement analysis & technical consultation

Upon receiving a client’s request, Truong Thinh’s technical team conducts a comprehensive analysis of the project requirements, covering factors such as scale, load capacity, installation environment, budget, and expected timeline. Based on these details, our engineers develop an optimized structural solution, complete with preliminary drawings and an initial cost estimate to help clients make well-informed decisions.

Step 2: Site survey & design planning

Once the proposed solution is approved, our survey team visits the site to collect real-world data such as ground elevation, geological conditions, and installation space. These parameters are integrated into Tekla Structures, SAP2000, and AutoCAD 3D models, ensuring design accuracy within ±1mm. Each drawing undergoes an internal QC checklist review before being officially submitted for client approval.

Step 3: Production at the factory

After design approval, production begins at our Binh Duong factory, where all cutting, welding, and surface finishing are performed in-house. Every material batch is verified with CO–CQ certificates and complies with ASTM or JIS standards to ensure clear origin and consistent quality. The beams are welded using 3-in-1 automatic welding machines, followed by Sa2.5 shot blasting, and finished with either three-layer epoxy coating or hot-dip galvanization, depending on project requirements. Each component is tagged with a unique QR code for full traceability and technical reference.

Step 4: Transportation, installation & handover

Once completed, steel beams are securely packaged and transported using 20–50 ton cranes with certified safety compliance (ATLĐ). Truong Thinh’s on-site construction team directly handles the installation process, working in coordination with the main contractor to ensure progress and safety. After assembly, the structure undergoes load testing and quality inspection in accordance with ISO 9001:2015 standards before official handover.

Step 5: Warranty & after-sales support

Upon handover, clients receive the as-built documentation and product quality certificates.All beam systems come with a 12-month structural warranty, and maintenance or periodic inspection services are available upon request. Truong Thinh also provides a 24/7 technical support channel, guaranteeing a response within 24 hours for any inquiry or issue. This transparent and proactive after-sales policy ensures long-term reliability and reinforces Truong Thinh’s commitment to lasting partnerships.

8. Services and support

Truong Thinh provides comprehensive technical services, including design consulting, structural analysis, and detailed drawing support. Customers can request product customization according to specific dimensions, load capacities, or aesthetic requirements.

Transportation is handled by 20–50 ton crane trucks with certified safety standards, ensuring all components arrive intact at the construction site. Every product is covered by a 12-month structural warranty, along with long-term maintenance and technical support policies.

With a solid technical foundation and a strong commitment to long-term partnerships, Truong Thinh not only delivers high-quality steel beams but also acts as a strategic partner for projects pursuing efficiency, sustainability, and safety. Contact us to discuss your project and discover how we can support your construction goals.