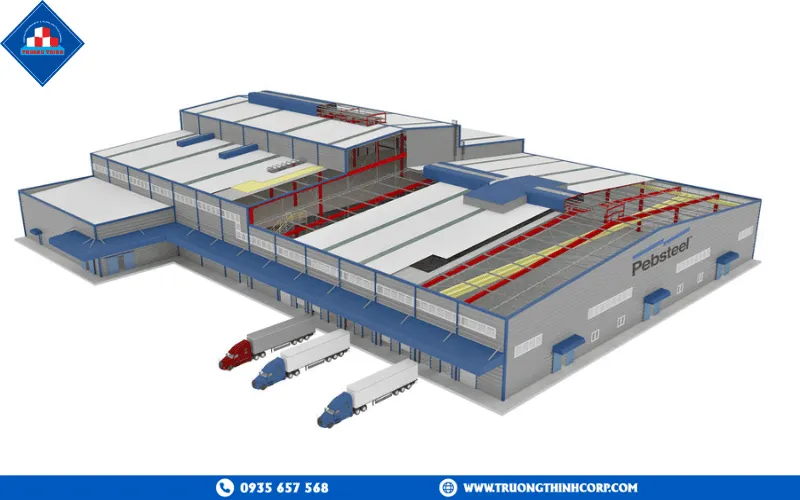

Production And Construction Of Pre-Engineered Steel Building

Today, pre-engineered steel buildings (PEB) have become an inevitable trend in the modern industrial era. This construction solution not only helps businesses optimize costs and shorten construction schedules but also ensures long-term performance and aesthetic value. With nearly two decades of experience in the design, fabrication, and erection of steel structures, Truong Thinh takes pride in being one of Vietnam’s leading and most trusted partners, providing comprehensive PEB solutions — from factory manufacturing to on-site erection and completion.

1. Benefits and advantages of pre-engineered steel buildings

Choosing a prefabricated house is not simply a cost decision, but a smart investment strategy that helps businesses optimize their resources comprehensively. This solution brings outstanding competitive advantages, from saving budget and speeding up project implementation progress, to ensuring construction quality according to international standards and being environmentally friendly.

1.1 Cost optimization

Compared to conventional reinforced concrete buildings, PEB structures can reduce total investment costs by 20–30%. The use of high-strength steel, efficient structural design, and automated fabrication processes significantly minimize material waste, labor expenses, and construction time.

At Truong Thinh, every stage from design and 3D modeling to erection is optimized to ensure maximum cost efficiency per square meter of construction.

1.2 Faster construction schedule

All steel components are pre-fabricated, surface-treated, and quality-inspected at the factory before delivery to the site. This allows the erection process to proceed rapidly, precisely, and safely, reducing construction time by up to 50% compared to traditional methods.

Such efficiency makes PEB systems an ideal choice for factories, warehouses, industrial zones, and logistics centers — projects that require early operation.

1.3 High – quality and precision

Each structural component is designed and verified using advanced software such as Tekla Structures, AutoCAD, and SAP2000, ensuring near-perfect accuracy. During erection, every joint, bolt, and base plate fits precisely, minimizing alignment errors and rework.

In addition, the Quality Control (QC) team supervises each production stage rigorously to ensure all finished products meet 100% of technical and durability standards before delivery.

1.4 Flexibility and expandability

The modular design of Pre-engineered Steel Buildings allows for easy dismantling, relocation, or expansion without affecting the existing frame system. Truong Thinh Corp provides flexible modular connections, enabling investors to scale up production space while saving significant future costs.

1.5 Environmentally friendly

Steel is 100% recyclable and environmentally safe. At Truong Thinh’s factory, all fabrication processes are tightly controlled to minimize noise, waste, and emissions, while using eco-friendly coatings and materials. As a result, each project by Truong Thinh not only ensures structural durability but also meets the “green building” standards of modern, sustainable construction.

2. Our pre-engineered steel building manufacturing standards

The quality of a prefabricated house is determined right from the production stage. At Truong Thinh, we apply a strict international standard system to the entire process, from selecting input materials, surface treatment, controlling production specifications, to testing the load-bearing capacity of each component.

2.1 Materials and standards

All primary frames, rafters, columns, and structural beams are fabricated using Q355, ASTM A572, SS400, Q235, and A36 materials. For detailed comparisons of grade selection and mechanical properties specific to steel beams, please refer to our material and testing reference. These materials feature yield strengths (Fy) ranging from 245–355 MPa, providing excellent load-bearing capacity, ductility, and stability in industrial environments.

Before fabrication, all incoming steel materials undergo strict chemical composition and mechanical property inspections, accompanied by full CO and CQ certificates of origin and quality. Truong Thinh’s manufacturing plant operates under the ISO 9001:2015 Quality Management System, adhering to rigorous QA/QC procedures throughout every production stage.

2.2 Dimensions and fabrication specifications

Web and flange plates are processed with thicknesses ranging from 4.5mm to 12mm, and member widths from 217mm to 2101mm. Equipped with advanced CNC cutting, welding, and drilling systems, Truong Thinh Corp can fabricate with high precision according to custom design drawings — from compact workshops to large-scale industrial plants spanning tens of thousands of square meters.

All weld joints are executed by automatic submerged arc welding (SAW/FCAW) systems, ensuring consistency, strength, and aesthetic weld finishes. Each welded component undergoes ultrasonic testing (UT), paint adhesion measurement, and final inspection in compliance with ASTM 3834 and EN 1090 standards.

2.3 Structural strength and load capacity

Thanks to high-grade steel and structural modeling by SAP2000 software, Truong Thinh’s products achieve outstanding axial, bending, and torsional resistance. Load-bearing parameters are flexibly designed to suit each project — including crane loads from 5 to 50 tons, or wind resistance up to 180 km/h. Each steel frame undergoes simulation testing and real-world validation, ensuring absolute safety and reliability throughout the building’s lifespan.

2.4 Surface preparation and coating

Before painting, every steel component is shot blasted to Sa 2.5 standard, achieving a surface roughness (Ra) of 30–75 μm, which provides an ideal surface for paint adhesion and superior corrosion resistance.

Truong Thinh applies a high-performance industrial coating system, consisting of:

- Primer coat (Epoxy or Alkyd) – directly adheres to steel surfaces to prevent corrosion, with a film thickness of 50–75 μm.

- Top coat (Polyurethane or Epoxy) – protects and enhances appearance, resistant to UV rays, chemicals, and harsh weather, with each coat thickness of 40–60 μm.

The total coating thickness ranges from 100–200 μm, providing a service life of 5–15 years, keeping the structure durable and visually appealing over time. For marine or highly corrosive environments, Truong Thinh applies hot-dip galvanizing in accordance with ASTM A123, with zinc coating thicknesses from 70–100 μm, extending component lifespan to 20–50 years.

3. Detailed structure of a pre-engineered steel building

To create a complete, solid, and safe prefabricated house, each part is calculated and closely linked together. Basically, the structure of a prefabricated house includes three main components: the main load-bearing frame structure, the secondary structure for reinforcement, and the covering and finishing system to protect the building.

3.1 Primary framing (columns and rafters)

The primary frame serves as the backbone of the entire structure, defining its load-bearing capacity and overall stability. Visit our detailed specifications for steel columns to learn more about material grades, section types, and load-testing procedures. At Truong Thinh, columns and rafters are fabricated from built-up welded H-sections, using automated submerged arc welding (SAW) for maximum accuracy, uniformity, and structural integrity.

The quality of the primary framing system is the core foundation of Truong Thinh’s reputation — ensuring each project achieves long service life, safety, and sustainability under all operating conditions.

3.2 Secondary framing (purlins and bracings)

The secondary framing system, which includes C and Z purlins, roof bracings, and wall bracings, is manufactured from high-tensile galvanized steel with thicknesses ranging from 1.6 mm to 3.2 mm. These components transfer roof and wall loads to the primary frames, ensuring structural stability and reducing vibrations during operation. For detailed profiles, load tables, and installation notes on our steel purlins, please visit the dedicated product page.

Depending on project conditions such as site topography, climate, wind loads, and crane capacity, Truong Thinh designs and optimizes the bracing system to guarantee maximum structural safety and performance.

3.3 Cladding and finishing system

The cladding system comprises roof and wall panels, roller shutters, windows, gutters, skylights, and ventilation systems. Truong Thinh utilizes PU or EPS insulated panels and pre-painted galvanized steel sheets (PPGI), which provide excellent thermal and acoustic insulation while enhancing the building’s aesthetic appeal.

All accessories and components are precisely fabricated and installed according to detailed shop drawings, ensuring a tight, leak-proof, and durable envelope that maintains both functionality and visual harmony over time.

4. Steel structure manufacturing capacity at Truong Thinh factory

Behind every solid structure is a foundation of advanced manufacturing systems and highly skilled professionals. At Truong Thinh Corp, we continuously invest in state-of-the-art machinery, modern technology, and human expertise to ensure the highest quality in every project delivered.

4.1 Factory scale and technology

Truong Thinh’s manufacturing complex covers a total area of 25,000 m², including over 15,000 m² of production workshops. With a monthly production capacity of 1,200–1,500 tons of steel structures, the factory is capable of meeting the demands of large-scale domestic and international projects.

Our modern production line features CNC cutting, automated welding, and 3D drilling. To learn more about production tolerances, non-destructive testing procedures, and the assembly process specific to the frame of steel truss, please refer to our manufacturing and quality assurance documentation.

Through synchronized technological investment, Truong Thinh ensures high productivity, absolute precision, and consistent quality across every batch of fabricated steel components.

4.2 Engineering team and quality management

Truong Thinh currently employs over 680 personnel, including 15 design engineers, 6 QC supervisors, and more than 20 certified welders holding international welding licenses. All personnel receive periodic training on technical standards, safety protocols, and the company’s quality management system.

A three-stage QA/QC process (incoming materials – in-process fabrication – final inspection) is strictly implemented, ensuring every finished product meets the highest international standards before delivery.

4.3 Certifications and quality standards

- ISO 9001:2015 – International Quality Management System

- CO & CQ – Certificates of Origin and Quality for materials

- Manufacturing standards: JIS G3101, ASTM A36, A572, EN10025

- Export markets: Cambodia, Thailand, Singapore, the Philippines, and Australia

5. Representative projects

Truong Thinh’s success is not only reflected in numbers but also proven through real-world achievements. Below are two representative projects that highlight our capabilities in pre-engineered steel building (PEB) and structural steel design.

5.1 Sea fish lake – Export seafood processing factory

- Location: Chau Thanh District, An Giang Province

- Scale: 40,000 m²

- Completion: 2020

- Scope of Work: Structural design

- Project Description:

The investor developed a seafood processing factory in An Giang Province with a processing capacity of approximately 200 tons of raw materials per day. The facility operates under a closed-loop production system encompassing aquaculture, processing, and export. This integrated model ensures strict control over input materials, consistent product quality, and enhanced flexibility for export operations.

Within this project, Truong Thinh was responsible for the structural design of the processing workshops and cold storage facilities, ensuring compliance with industrial building standards in terms of structural integrity, production layout, and load-bearing capacity. The project was successfully completed in 2020, significantly contributing to the investor’s supply chain optimization and export expansion across the Mekong Delta region.

5.2 Gallery Wedding Book Space – Ho Chi Minh City, Vietnam

- Location: Ho Chi Minh City

- Type: High-end convention, exhibition, and event complex

- Scope of Work: Design, fabrication, and erection of the main steel frame, long-span roof trusses, and secondary structures

- Project Description:

This project features a distinctive architectural design with open spaces that demand both high aesthetic value and precision in steel structure fabrication. Truong Thinh implemented Tekla Structures 3D BIM modeling to synchronize the design, detailing, fabrication, and erection processes.

The Pratt truss system with spans from 24 to 28 meters was fabricated using A36 and ASTM A572 steel and coated with two layers of epoxy paint with a total thickness of 80 micrometers for enhanced corrosion resistance. For technical drawings, connection details, and fabrication notes on similar projects, please view our steel truss case study and specification sheet. The structure combines lightweight design with superior load-bearing capacity for roofing and suspended ceiling systems. All welding processes were performed using SAW/FCAW CO₂ technology in compliance with AWS D1.1 standards, and the three-level QA/QC system ensured geometric accuracy within ±2 mm. The result is a high-precision, visually impressive steel structure tailored for modern event spaces.

Alongside expanding its domestic market share, Truong Thinh Corp continues to strengthen its position in steel fabrication and export. Our steel trusses, built-up frames, long-span beams, and erection accessories have been exported to Cambodia, Laos, Myanmar, Thailand, the Philippines, Malaysia, Singapore, and Australia. Each shipment is accompanied by CO, CQ certificates, mechanical test reports, and detailed technical documentation, ensuring full traceability and compliance with international standards.

6. Our project workflow

To ensure that every project is implemented in the most transparent, efficient, and optimal way for customers, Truong Thinh applies a professional 4-step cooperation process. This process creates a seamless workflow, from the initial idea reception to the handover of a completed project.

Step 1: Requirement analysis & technical consultation

Upon receiving project information, our team of engineers and technical consultants conducts a detailed analysis of the building’s characteristics, intended function, and investment budget. Based on the collected technical data, Truong Thinh provides an optimized steel structure solution — balancing structural performance, aesthetics, and construction cost — to help clients select the most efficient and suitable option for their project.

Step 2: Site survey & engineering design

After the preliminary concept is approved, our technical team performs an on-site survey to assess terrain, soil conditions, and construction constraints. Using specialized software such as Tekla Structures, SAP2000, and AutoCAD 3D, our engineers model the entire structure in 3D, perform load analysis, and determine accurate dimensions, spans, and connection details.

A complete set of technical drawings is then submitted to the client for review and approval prior to fabrication, ensuring all specifications are clearly defined and consistent.

Step 3: Fabrication & production at the factory

Once the drawings are approved, the fabrication process begins at our CNC-automated production line, operated under the ISO 9001:2015 Quality Management System. Each steel component undergoes strict procedures including cutting – welding – shot blasting – painting, in compliance with industrial standards.

The QC department performs full inspection on dimensions, tolerances, weld quality, surface coating thickness, and CO/CQ certification prior to dispatch, guaranteeing the highest product quality.

Step 4: Erection & project handover

After transportation to the site, all steel components are erected following standard installation procedures, ensuring dimensional accuracy within ±1 mm. Our erection team adheres strictly to safety regulations, closely monitoring schedule, alignment, and quality throughout every stage.

Before handover, the completed structure undergoes a comprehensive inspection and is delivered with a full as-built dossier, CO/CQ certificates, and a 12-month warranty package.

7. Frequently asked questions (FAQs)

Below are some of the most common questions clients often ask when learning about pre-engineered steel buildings and Truong Thinh’s services.

7.1. Are pre-engineered steel buildings durable?

Yes — they are extremely durable and stable throughout their entire service life.

All primary frames are fabricated from SS400 or ASTM A36 steel with a yield strength of 245–355 MPa and tensile strength up to 560 MPa, ensuring excellent resistance to wind, storms, and seismic loads in compliance with TCVN and ASTM standards.

All steel surfaces are shot-blasted to Sa2.5 and coated with industrial-grade epoxy paint, allowing the building to maintain structural integrity for over 50 years without corrosion.

7.2. Are pre-engineered steel buildings fire-resistant?

Yes. Truong Thinh applies fireproof coating systems compliant with ASTM E119, capable of withstanding temperatures of 1,000–1,100°C for up to 120 minutes.

Additionally, buildings can be combined with fire-rated insulated panels such as PU, EPS, or Rockwool sandwich panels, which enhance both thermal insulation and fire safety for factories, warehouses, and even residential applications.

7.3. Are pre-engineered buildings more expensive than concrete structures?

No. In fact, PEBs can reduce total construction costs by 20–30% compared to traditional reinforced concrete structures.

This cost efficiency is achieved through:

- 40–50% shorter construction time

- Reduced labor and formwork costs

- Ease of expansion and material reusability

7.4. How long does it take to complete a pre-engineered steel building project?

The construction duration depends on the project’s scale and complexity. For factories ranging from 10,000–20,000 m², the average construction time is 3–5 months, including design, fabrication, and erection phases. Larger projects may take 6–8 months, yet still 30–40% faster than concrete buildings due to Truong Thinh’s integrated design–fabrication–installation process.

7.5. Are pre-engineered steel buildings suitable for civil or commercial projects?

Absolutely. Thanks to their flexible design and aesthetic appeal, pre-engineered steel buildings are widely used for showrooms, commercial centers, restaurants, villas, modern homes, and even high-rise office towers. PEBs are not only a modern construction solution but also a smart investment, helping businesses save costs, ensure long-term quality, and maximize operational efficiency.

With strong production capabilities and years of proven experience, Truong Thinh Corp has established itself as a trusted name in manufacturing and constructing pre-engineered steel buildings for both domestic and international markets. We deliver durable, cost-efficient, and high-quality steel structures that stand the test of time. Contact us to discuss your project and find the most suitable solution for your needs.