Manufacturing and Processing High Quality Gusset Plates

In every steel structure, whether it is a factory, warehouse, roof truss, crane, or pre-engineered building, gusset plates may appear small but serve as essential connection points that ensure overall stability and effective load transfer between columns, beams, and braces. Produced on advanced CNC lines with high-quality materials such as SS400, Q235, and A36, and protected by epoxy coating or hot-dip galvanizing, Truong Thinh’s gusset plates offer exceptional precision, strength, and long-lasting durability for both domestic and international projects.

1. Applications of gusset plates

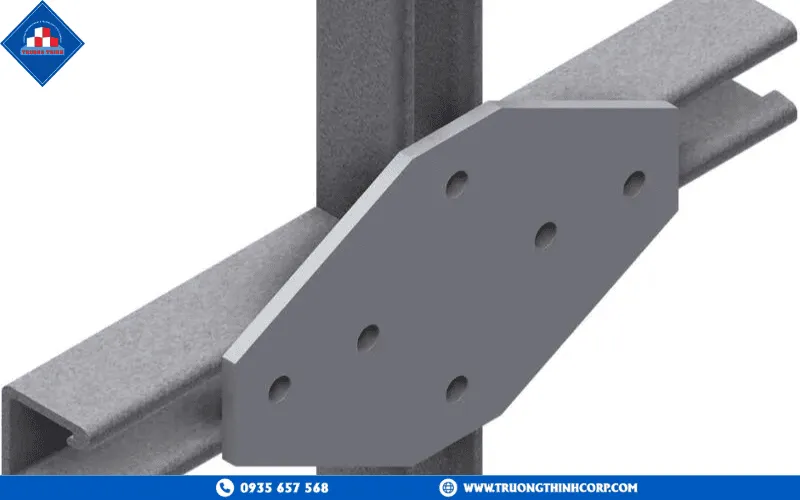

Before exploring the production process, let’s look at the role and applications of gusset plates in real-world structures. Understanding where and why they are used reveals why accuracy and quality are top priorities in every steel structure project. In modern industrial construction, gusset plates appear in most load-bearing connections. Depending on function, they may serve to connect, anchor, or transfer loads between key structural components.

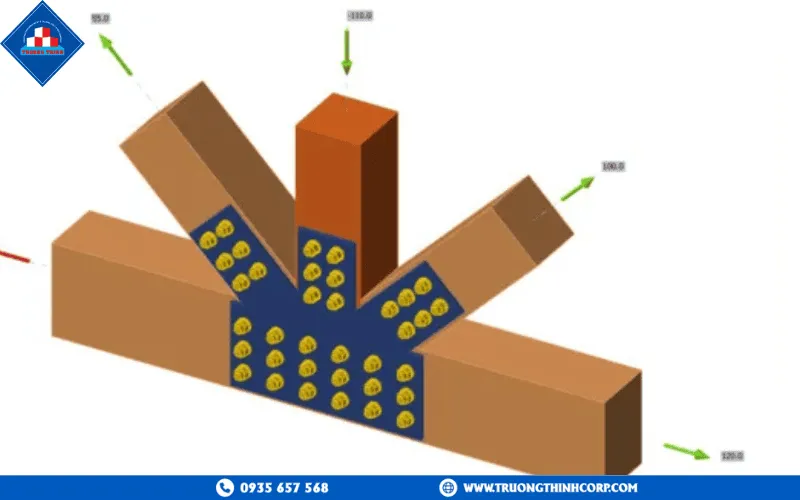

In steel truss systems, gusset plates are used to connect bracing and load-bearing members, distributing loads evenly and preventing torsion. In large-scale projects such as bridges, factories, and pre-engineered buildings, they connect columns (H-beams), beams (I-beams), and Z-frames, ensuring uniformity and overall stability.

For heavy-duty structures such as crane systems, deck floors, and large canopies, gusset plates serve as direct load transfer points between the structural steel and the foundation, working in conjunction with components like the steel base column that firmly anchors the entire frame to the concrete base. High-quality plates help reduce vibration, prevent distortion, and enhance load-bearing capacity. Precision-engineered gusset plates also simplify erection, reduce installation time, and lower long-term maintenance costs—one reason why many contractors and investors choose Truong Thinh’s gusset plates for their projects.

2. Production process and quality control at Truong Thinh factory

To meet the stringent demands of technical precision, mechanical strength, and durability, Truong Thinh has established a fully controlled in-house manufacturing process comprising three main stages: design – fabrication – finishing, all compliant with ISO 9001:2015 standards.

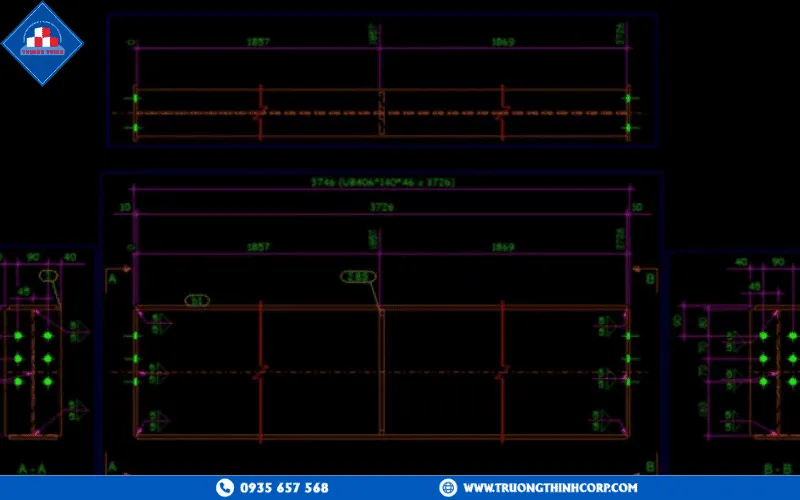

2.1 Stage 1: Design – The foundation of accuracy

Every gusset plate begins with a detailed design drawing that ensures dimensional precision and structural compatibility. Truong Thinh’s engineering team uses Tekla Structures, AutoCAD, and SAP2000 to model plate geometry with exact parameters such as size, bolt-hole layout, thickness, and load capacity. These details are carefully coordinated with the connected steel column drawings, including anchor bolt patterns, flange details, and connection plates, to guarantee precise alignment during installation.

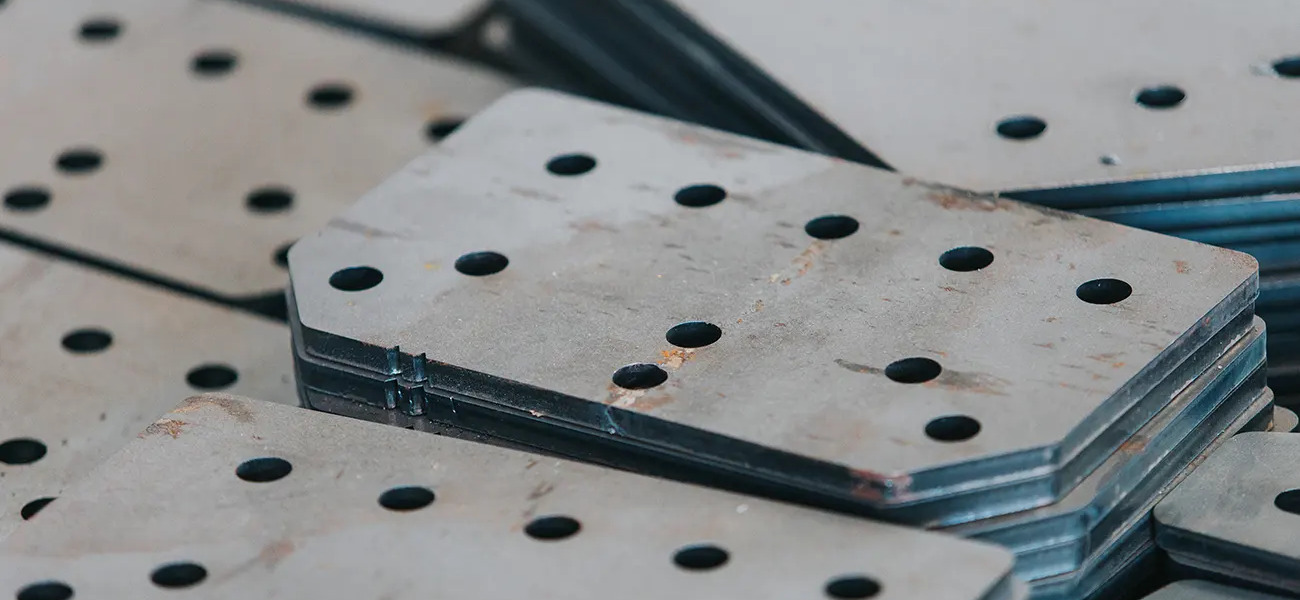

2.2 Stage 2: Automated cutting and welding – Precision to every millimeter

Once approved, production begins at Truong Thinh’s 25,000m² facility equipped with CNC plasma–oxy gas cutting machines, automated drilling and punching systems, maintaining tolerances within ±0.5mm. Steel plates are sourced from certified suppliers with CO, CQ documents, meeting ASTM 384 and JIS G3101 standards (SS400, Q235, A36 grades), with yield strength 245–355 MPa and tensile strength 400–510 MPa.

Fabrication includes cutting, drilling, stamping, and welding (for composite plates). All welds are executed using semi-automatic and robotic welding systems to AWS D1.1 standards, ensuring aesthetics, strength, and reliability.

Finished products undergo mechanical testing, flatness and squareness verification, and dimensional inspection using specialized gauges. Non-conforming parts are reworked or rejected before proceeding.

2.3 Stage 3: Surface finishing and protection – Strength meets aesthetics

After fabrication, plates are shot-blasted to Sa 2.5 surface cleanliness with roughness Ra 15–50 μm.

Depending on project requirements, plates are finished by:

- Two-layer epoxy coating with total thickness 80–100 μm, customizable by RAL color; or

- Hot-dip galvanizing with zinc thickness 80–100 μm, providing 10–15 years of outdoor corrosion protection.

All products undergo final quality control (Final QC), including coating thickness, adhesion, and visual inspection, before being labeled, packaged, and shipped.

3. Manufacturing capacity at Truong Thinh

To ensure consistent quality and fast delivery for hundreds of projects annually, Truong Thinh continuously invests in state-of-the-art technology, skilled manpower, and a robust quality management system.

3.1 Factory and technology

Located in Binh Duong, the 25,000m² steel structure plant houses advanced machinery including 6–12m CNC cutting lines, 3D drilling systems, plate milling machines, hydraulic punching presses, and integrated 3-in-1 automatic welding lines.

Each gusset plate passes through a closed-cycle line of shot blasting – coating – packaging, minimizing human error. With a capacity of 1,200–1,500 tons/month, Truong Thinh meets tight project schedules both domestically and internationally. All operations comply with ISO 9001:2015, under a continuous QC/QA monitoring system from material input to packaging.

3.2 Engineering team and quality assurance

Beyond technology, people are the foundation of Truong Thinh’s sustainable value. The company employs over 680 staff, including 120 mechanical engineers. All welders are AWS/JIS-certified, and CNC operators receive regular training.

The QC system is structured in three layers: IQC (Incoming Quality Control), PQC (Process Quality Control), and OQC (Outgoing Quality Control)—ensuring every product meets the highest mechanical and visual standards before dispatch.

3.3 Certifications and standards

Truong Thinh’s credibility is reinforced by international certifications. All products carry CO–CQ documentation, mechanical test reports, and comply with ASTM 384, JIS G3101, and BS EN10025 standards. The factory is certified to ISO 9001:2015, and Truong Thinh exports steel structures to Singapore, Malaysia, Cambodia, and other markets, affirming Vietnam’s global presence in the steel structure industry.

4. Benefits of choosing Truong Thinh gusset plates

Choosing Truong Thinh means more than just purchasing a product—it’s about receiving a comprehensive structural solution from design to delivery and warranty.

Clients benefit from:

- Free technical consultation to determine suitable plate type, thickness, bolt-hole layout, and surface finish.

- Custom fabrication with thickness from 6–40mm and tolerance of ±0.5mm.

- Dedicated transport fleet (5–20 tons) ensuring safe and timely delivery.

- 12-month warranty for all products, with replacement or rework in case of technical defects.

5. 5-Step collaboration process

To guarantee efficiency, transparency, and quality, Truong Thinh applies a 5-step project workflow, reducing delivery time by up to 30% compared to conventional methods.

5.1 Requirement analysis & technical consultation

Engineers analyze project data—scale, load design, site conditions, and budget—to propose the most efficient structural solution with preliminary drawings and cost estimation.

5.2 On-site survey & final design

The survey team collects real-world data (elevation, soil conditions, assembly space) and updates it in Tekla, SAP2000, and AutoCAD 3D. Drawings are checked internally via QC checklist before client approval.

5.3 Manufacturing at Truong Thinh factory

Production starts using certified ASTM/JIS materials with full CO–CQ traceability. Processes include automated cutting, welding, shot blasting, and coating to ensure precision and durability. Each component is tagged with a QR code for traceability.

5.4 Transport, installation & handover

Finished components are packed securely and transported using 20–50 ton certified cranes. The on-site erection team coordinates with main contractors to ensure safe, accurate, and on-time assembly. All works are tested and accepted per ISO 9001:2015.

5.5 Warranty & after-sales support

Clients receive completion records, inspection reports, and quality certificates. All products are covered by a 12-month structural warranty and supported by 24/7 technical service. Truong Thinh guarantees response within 24 working hours for any request.

6. Customer service and support

Clients are directly supported by Truong Thinh’s experienced engineering team, who provide customized design and technical assistance—covering material selection, dimensions, bolt-hole layout, coating, or galvanizing methods.

The company’s 7–20 ton transport fleet ensures safe and punctual delivery. Every package is carefully labeled, padded, and protected from surface damage during transport. All gusset plates include a 12-month warranty, with optional maintenance and material testing services to ensure long-term performance.

In every project, gusset plates serve as the foundation of stability — small yet crucial components that reinforce the strength of an entire structure. Choosing the right manufacturer ensures safety, durability, and long-term value. With advanced production lines, professional engineers, and adherence to international standards, Truong Thinh Corp delivers precise, sustainable, and cost-effective gusset plate solutions for all industrial construction projects. Contact us to request a quotation or discuss your project requirements with our engineering team.