Factory-Manufactured Steel Truss Supplier

Steel trusses serve as the backbone of every structure, enhancing durability while reducing maintenance costs, optimizing construction schedules, and ensuring long-term investment efficiency. Truong Thinh Corp is a pioneer in the design, fabrication, and installation of steel trusses in Vietnam. With a modern factory covering more than 25,000 square meters and a monthly capacity of 1,200 to 1,500 tons, Truong Thinh has supplied thousands of tons of high-quality steel trusses for factories, commercial centers, bridges, tunnels, and industrial facilities across the country.

1. Advantages of Truong Thinh steel trusses

Produced from international-grade steel, processed with advanced surface treatment technology, and inspected under strict quality control, Truong Thinh’s steel trusses ensure superior precision and long-lasting strength for every project.

1.1 High strength to weight ratio

Truong Thinh utilizes internationally certified materials such as SS400, Q235, A36, and Q355/A572, manufactured in compliance with ASTM A36/A572, JIS G3101, and EN10080 standards. With yield strengths ranging from 245 MPa to 355 MPa, our truss systems achieve optimal strength-to-weight ratios—providing excellent load-bearing capacity while minimizing foundation loads. This brings significant economic benefits, especially for large-scale or wide-span structures.

1.2 Cost and time efficiency

The entire design and fabrication process is fully automated using CNC technology, including plasma cutting, CO₂ welding, and 3D CNC drilling systems. This integrated workflow keeps dimensional tolerance under 1 mm, shortens installation time by 20–30%, and reduces labor and operation costs. Standard truss dimensions reach up to 12 m in length and 1.5–2.1 m in height—suitable for warehouses, factories, and commercial buildings of various configurations.

1.3 Exceptional durability and longevity

Each product is finished with a two-layer epoxy coating (Primer + Topcoat) or hot-dip galvanizing for superior corrosion resistance, even under harsh environmental conditions. Coating thickness ranges from 60–75 μm for standard environments and up to 80–100 μm for coastal or heavy industrial zones. With proper protection, Truong Thinh trusses can last over 50 years without frequent maintenance—significantly reducing lifecycle costs.

1.4 Design flexibility

All truss components are modeled using Tekla Structures and SAP2000, enabling accurate 3D simulation and load analysis. Our engineering team customizes designs to meet project-specific requirements—ranging from Fink, Warren, Pratt, and Howe trusses to Scissor and King Post systems—balancing technical performance with architectural aesthetics.

1.5 Sustainability

Truong Thinh’s products are manufactured under the ISO 9001:2015 quality management system, using certified CO–CQ materials that are 100% recyclable. Our production lines are optimized for energy efficiency and CO₂ emission reduction, aligning with global green building and sustainable development trends.

1.6 Architectural aesthetics

Beyond structural performance, Truong Thinh’s steel trusses feature smooth, uniform finishes and refined forms. Their open-frame design allows for optimal ventilation and natural lighting. For an in-depth look at component layouts and connection details, please refer to our dedicated guide to the steel frame.

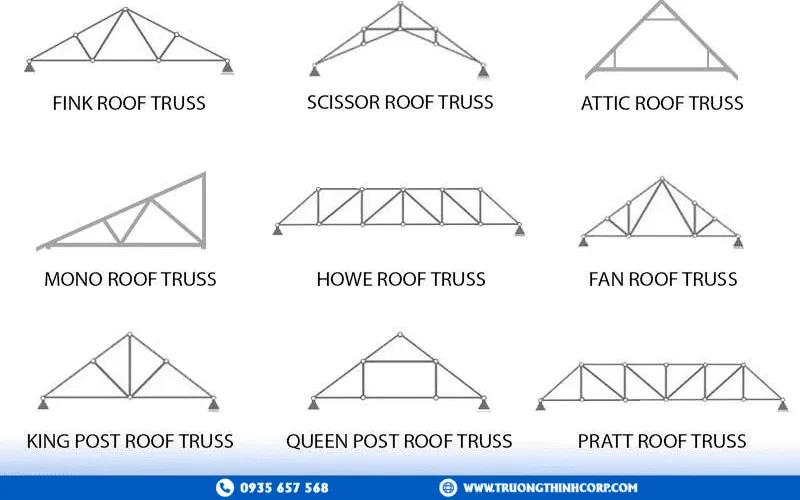

2. Popular types of steel trusses

Steel trusses are frameworks of interconnected members forming triangular or space structures that efficiently distribute loads. The structural frame of a steel truss plays a crucial role in ensuring overall rigidity and effective load transfer. Common types include:

- Fink Truss: Common for medium-load roofs in factories and bridges.

- Pratt Truss: Offers optimal force distribution; ideal for warehouses and industrial buildings.

- Howe Truss: Easy to fabricate and strong under heavy loads; widely used in bridges and large-span roofs.

- Warren Truss: Equilateral triangular form for evenly distributed stress.

- Gable & Scissor Trusses: Suitable for steep or architecturally refined roof designs.

- King Post, Flat, and Lean-to Trusses: Common in factory extensions, shelters, and open structures.

3. Practical applications of steel trusses

Truong Thinh Steel Trusses have been successfully applied across various sectors — from industrial factories and warehouses to commercial centers, bridges, tunnels, and stadiums. With advantages such as lightweight structure, ease of assembly, high precision, and exceptional load-bearing capacity, Truong Thinh’s products consistently meet the most demanding technical standards required by both domestic and international investors.

4. Steel truss manufacturing process at Truong Thinh factory

The production process at Truong Thinh is fully integrated and closed-loop, consisting of three main stages: Design – Fabrication – Finishing, with each stage undergoing strict quality control before final delivery.

4.1 Stage 1: Design

The engineering team utilizes Tekla Structures and SAP2000 software to model the structure, calculate load capacities, and optimize every truss member detail. Each drawing is cross-checked between the design and production departments to ensure near-perfect accuracy. This stage also determines key structural parameters such as dead load, live load, and safety factors.

4.2 Stage 2: Automated cutting and welding

All incoming steel materials are inspected and verified with CO and CQ certificates before entering production. The fabrication process includes CNC plasma cutting, CNC punching and drilling, and CO₂ automatic welding. The same automated roll-forming and CNC punching lines are used to produce our high-precision steel purlin profiles, which are trial-assembled and inspected (UT or MT where applicable) before shot-blasting and coating.

4.3 Stage 3: Finishing and surface protection

Depending on project requirements, the steel trusses are either coated with a two-layer epoxy system (Primer + Topcoat) or hot-dip galvanized to standards Sa2.5 – Ra15–50. This surface protection technology enhances corrosion resistance, allowing the trusses to withstand Vietnam’s tropical humid climate and extending their service life for decades.

5. Steel truss production capacity at Truong Thinh

To ensure consistent quality, fast project delivery, and the ability to handle multiple large-scale projects simultaneously, Truong Thinh Corp has made substantial investments in factory infrastructure, modern technology, a highly qualified engineering team, and an international-standard quality management system. As a result, Truong Thinh’s steel trusses consistently achieve outstanding precision, strength, and aesthetics, meeting the most stringent technical requirements from both domestic and international clients.

5.1 Scale and technology

Truong Thinh’s steel structure manufacturing plant, located in Tan Uyen, Binh Duong, spans over 25,000 m², including dedicated zones for fabrication, shot blasting & painting, and assembly. The production line is equipped with advanced machinery such as 6–12m CNC plasma cutting machines, 3D drilling machines, 3-in-1 CO₂ automatic welding systems, beam straightening machines, and 20-ton overhead cranes.

Each truss component undergoes a closed process of shot blasting – coating – inspection – packaging, minimizing dimensional deviations and ensuring surface finishes that meet Sa2.5 – Ra15–50 standards. With a monthly production capacity of 1,200–1,500 tons, the factory can simultaneously supply multiple industrial, commercial, and infrastructure projects. All manufacturing activities are managed under the ISO 9001:2015 quality management system, with dedicated QC/QA teams overseeing every stage — from raw steel inspection to fabrication and final packaging.

5.2 Engineering team and quality management

Truong Thinh employs over 680 personnel, including 120 mechanical and civil engineers directly involved in the design, production, and inspection processes. All welding engineers hold international certifications (AWS, JIS), while CNC operators receive regular technical training, ensuring synchronized and accurate production operations.

The company’s three-tier quality control system consists of:

- IQC (Incoming quality control): Inspection of raw materials.

- PQC (Process quality control): Monitoring during production.

- OQC (Outgoing quality control): Final inspection before delivery.

Through this three-layer inspection process, every steel truss is thoroughly verified for geometric accuracy, load-bearing performance, and weld quality, guaranteeing that the final product meets the highest technical and aesthetic standards.

5.3 Certifications and quality standards

Truong Thinh’s reputation is reinforced not only by hundreds of completed projects but also by its compliance with international certifications and strict production standards. All steel truss products are accompanied by Certificates of Origin (CO), Certificates of Quality (CQ), and mechanical–physical test reports. The factory is ISO 9001:2015 certified, and all raw materials and production processes comply with ASTM A36/A572, JIS G3101, and BS EN10025 standards.

With a strong technical foundation and comprehensive quality control, Truong Thinh not only serves the domestic market but also exports steel trusses to Cambodia, Malaysia, and Singapore, affirming its position as a leading Vietnamese steel structure brand in the regional market.

6. Our featured projects

Over more than 18 years of development, Truong Thinh Corp has partnered with hundreds of domestic and international investors, delivering numerous large-scale industrial, commercial, and civil construction projects. Below are two representative projects that demonstrate Truong Thinh’s expertise in steel structure design and erection, as well as its outstanding schedule performance.

6.1 Co.op Mart Hong Ngu supermarket project – Dong Thap province

- Location: Hong Ngu Town, Dong Thap Province

- Investor: Saigon Co.op (Ho Chi Minh City Union of Trading Cooperatives)

- Construction period: 2018

- Scale: 3,000 m² of floor area; 1,200 m² of parking area

- Scope of work: Design – Fabrication – Erection of steel structure and infrastructure

- Project description:

The Co.op Mart Hong Ngu Supermarket is a key commercial project in Dong Thap Province, designed with a modern pre-engineered steel frame structure that provides a spacious, energy-efficient, and well-ventilated environment. With a total investment of VND 62 billion, the project includes various components such as the main shopping hall, entrance lobby, parking area, and auxiliary technical facilities.

Truong Thinh Corp was responsible for the entire steel structure package, from detailed engineering design, fabrication at the Binh Duong factory, to on-site erection. By applying a flexible project management system and CNC-based fabrication technology, Truong Thinh successfully completed the project on schedule, ensuring superior quality and aesthetics in line with Saigon Co.op’s premium retail standards.

6.2 Can Dang market project – An Giang province

- Location: Can Dang Commune, Chau Thanh District, An Giang Province

- Investor: People’s Committee of Chau Thanh District, An Giang Province

- Construction period: 2020

- Scale: 2,500 m² of construction area

- Scope of Work: Fabrication and erection of steel structure and roofing system

- Project Description:

The Can Dang Market is one of the key public markets in Chau Thanh District, upgraded to better serve the local trading and community needs. Truong Thinh was selected as the steel structure and roofing contractor, responsible for the design, fabrication, and erection of the entire space truss system, columns, beams, and pre-engineered steel roofing.

The structure features a lightweight steel frame with large spans, optimizing usable space while ensuring natural ventilation and lighting. All steel components were fabricated at Truong Thinh’s Binh Duong factory, using ASTM-standard materials and coated with anti-corrosion epoxy paint, perfectly suited for the hot and humid climate of the Mekong Delta.

7. Why choose Truong Thinh as your steel truss supplier

With nearly 20 years of experience in the industrial steel structure sector, Truong Thinh Corp has partnered with hundreds of factory, warehouse, and infrastructure projects nationwide. This extensive hands-on experience enables the company to fully understand the specific characteristics of each project type and deliver the most suitable, safe, and efficient steel truss solutions for every client.

Truong Thinh implements a strict quality control system in compliance with ISO 9001:2015 and international standards such as ASTM, JIS, and EN. All products undergo mechanical and physical property testing, are fully certified with CO–CQ documentation, and are supervised by an independent QC/QA department — ensuring the highest levels of strength, precision, and aesthetics before delivery.

Beyond manufacturing, Truong Thinh also provides professional design consultation and on-site installation services, supported by an experienced team of engineers using advanced software such as Tekla Structures and SAP2000. The company accompanies clients throughout every project stage — from design and fabrication to erection and warranty, ensuring complete confidence and satisfaction throughout the entire lifecycle of the structure.

With competitive pricing, on-time delivery commitments, and dedicated customer support, Truong Thinh Corp has become a trusted partner of numerous investors, contractors, and FDI enterprises. Each steel truss is not merely a structural component but a symbol of quality, credibility, and responsibility that Truong Thinh consistently upholds in every project.

8. Our collaboration process

To ensure every steel truss project is executed efficiently, transparently, and with maximum performance, Truong Thinh Corp has developed a 5-step integrated collaboration process that tightly connects the design, fabrication, erection teams, and the client/investor. This process not only enables comprehensive quality control but also helps reduce construction time by 20–30% compared to conventional methods, delivering real value to customers.

Step 1: Requirement analysis and technical consultation

Upon receiving the client’s request, Truong Thinh’s engineering team conducts a detailed analysis of project factors such as building scale, design loads, erection space, construction conditions, and budget. Based on these parameters, engineers propose the optimal truss structure solution, along with preliminary drawings and cost estimates, enabling clients to evaluate and select the most suitable option for their actual project needs.

Step 2: Site survey and detailed design

After the technical proposal is approved, Truong Thinh’s survey team visits the construction site to collect field data including ground elevation, foundation coordinates, soil characteristics, and installation space conditions. This data is processed using specialized software such as Tekla Structures, SAP2000, and AutoCAD 3D to create a detailed structural simulation with a dimensional tolerance of less than ±1 mm. Before submission for client approval, all drawings undergo internal QC checklist review to ensure constructability, safety, and compliance with structural requirements.

Step 3: Fabrication at Truong Thinh factory

Once the design is approved, fabrication begins at Truong Thinh’s Binh Duong factory. All raw materials are fully certified with CO–CQ documentation and conform to ASTM A36/A572 and JIS G3101 standards. The manufacturing process includes CNC cutting, drilling, automatic CO₂ welding, shot blasting, and coating, utilizing 3-in-1 CNC and automated welding lines to ensure high precision and productivity.

After fabrication, each component is shot-blasted to Sa2.5 standard and coated with 2–3 layers of epoxy paint or hot-dip galvanized depending on project requirements. Every truss set is labeled with a unique QR code for easy traceability of material origin, specifications, and production details.

Step 4: Transportation, erection, and handover

Completed components are safely packaged and transported using tractor-trailers and 20–50 ton cranes equipped with full safety certifications (ATLĐ). Truong Thinh’s erection team works closely with the main contractor to ensure schedule adherence, site safety, and precision alignment in every truss connection and joint.

Before final handover, all structures undergo load testing and inspection in accordance with ISO 9001:2015, verifying that all technical parameters meet both design specifications and international construction standards.

Step 5: Warranty and after-sales support

Upon project completion, clients receive a complete documentation package including as-built drawings, inspection reports, CO–CQ certificates, and technical data sheets. All trusses and gusset plates are covered by a 12-month structural warranty, and Truong Thinh provides scheduled maintenance and 24/7 technical support.

All service requests are addressed within 24 working hours, demonstrating Truong Thinh’s long-term commitment to client satisfaction. This dedicated after-sales policy ensures that each project remains stable, durable, and safe throughout its entire operational lifecycle.

9. Services and support

In addition to steel truss products, Truong Thinh provides comprehensive technical consulting, design assistance, safe transportation, and flexible warranty policies. All products come with a 12-month standard warranty, lifetime technical support, and design adjustments upon request to accommodate real-site conditions.

Truong Thinh steel trusses combine quality, technology, and reliability to deliver durable and efficient structural solutions. Backed by advanced engineering and expert craftsmanship, we are a trusted partner in Vietnam’s and the region’s steel structure industry. Contact us for tailored solutions to your project.